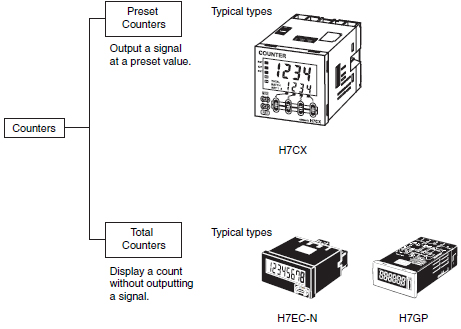

OMRON provides Preset Counters, Totalizing Counters, Time Counters and Electromagnetic Counters.

The term counter is derived from the word count. It is fairly simple for people to count ten or twenty objects, but larger numbers make counting increasingly difficult. Counters outperform people when it comes to counting accurately.

For example, the devices that are used by people on street corners to count pedestrians in traffic surveys are one type of counter. They are a good replacement for people because they accurately count pedestrians and remember the count even with very large numbers.

Some game machines accurately and automatically calculate the number of items you have won. It would be a significant problem for amusement businesses if they did not count accurately.

The basketball gaming machines at amusement parks count the number of baskets made within a certain amount of time.

Even here, Counters count with high accuracy to enable the machines to display the correct number of baskets.

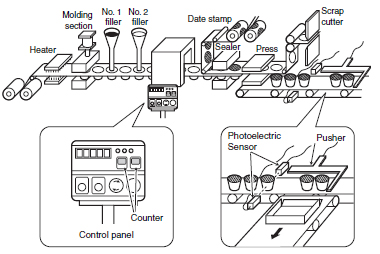

The following example shows the use of Counters in automated machinery.

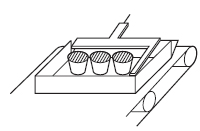

On a pudding production line, a Photoelectric Sensor detects the finished products. If the number three is preset in the Counter and it receives a Photoelectric Sensor signal three times, the Pusher (see note) pushes the three pudding containers into a box.

Note: Pusher: Pushing device

The following section describes the input, control, and output signal sequence in a boxing process.

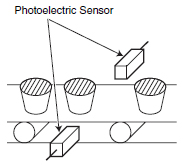

A Photoelectric Sensor is an input device that detects an object when that object blocks light. Each time the light is blocked, the Photoelectric Sensor sends a signal to the Counter.

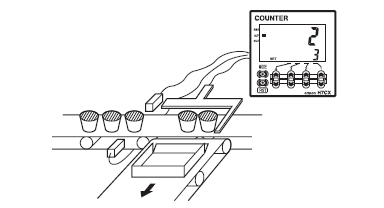

Preset the number three in the Counter. The Counter will then count the number of signals from the Photoelectric Sensor and sends a signal to the Pusher (i.e., the output device) after the Counter receives a signal for the third time.

When the Pusher receives the output signal from the Counter, it pushes the three pudding containers into a box.

As you can see, the Counter is involved in every step of the input, control, and output signal sequence.

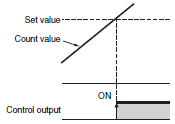

A Preset Counter is a control device that counts the number of input signals until a preset value is reached. It then outputs a signal to activate the next output device.

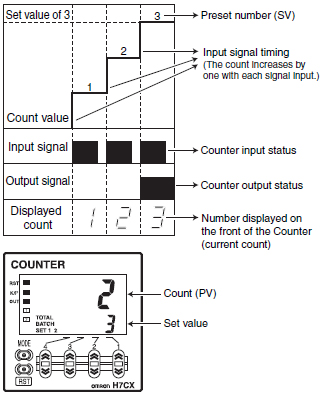

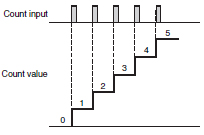

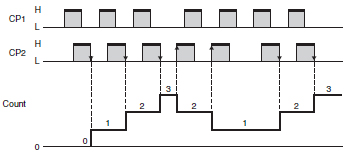

See the following timing chart for the input and output signal timing in the boxing process for pudding.

1. When the first pudding container passes by the Photoelectric Sensor, the Sensor sends a signal to the Counter and 1 will be displayed.

2. When the next pudding container passes by the Photoelectric Sensor, 2 will be displayed.

3. When the third pudding container passes by the Photoelectric Sensor, 3 will be displayed. Because this number matches the set value, the Counter will output a signal.

The preset number is called the set value (or preset value). When that number is reached, a signal is output. This is often referred to counting up, but it means the same as timer setting or time up.

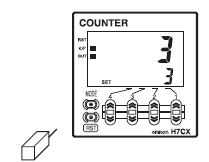

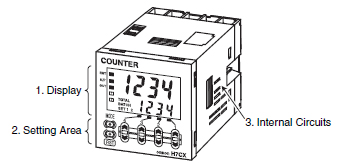

1. Display: Displays the Counter value.

2. Setting Area: Enters settings from the keys on the front panel.

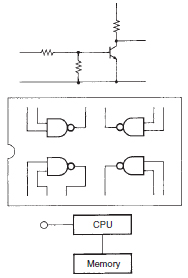

3. Internal Circuits: The internal circuits count the number of input signals, compare the count to the set value, and then output a signal when the two values match.

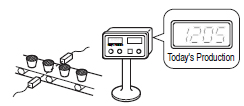

The term preset in Preset Counter means that you can set a value in advance. A Preset Counter may be one that counts up and outputs a signal at a predetermined point or it may be a Total Counter that strictly counts without outputting a signal. The Total Counter is often used when you only have to display a production count for example.

(Number of Puddings Counted)

The Counter uses a Photoelectric Sensor to count the number of puddings produced and then displays the number that it counted.

Counters are classified into two groups according whether they produce an output or not.

A counter which mainly consists of transistors, ICs, micro-computers, etc.

A counter which performs counting by energizing or de-energizing the built-in electromagnet.

A counter whose control output operates when it counts up to a set value.

A counter which indicates the total value of the counting inputs and is not provided with a control output.

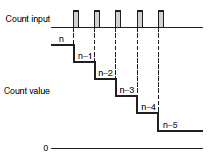

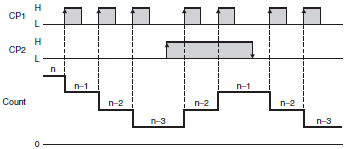

A counter with a subtract input and thus capable of counting in descending order.

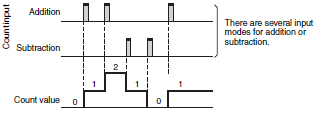

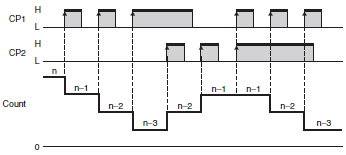

A counter with the capability of counting in an ascending or descending order, depending on the up-down inputs. Also called a reversible counter.

The maximum counting speed at which the display or output section of the counter operates accurately without miscounting. The maximum counting speed is expressed in units of counts per second (cps).

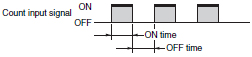

The ratio of the ON signal time of a given input signal to the OFF signal time of the same input signal. The maximum counting speed of each counter is determined by a counting input signal with an ON-OFF ratio of 1:1.

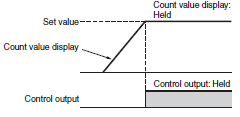

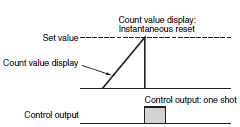

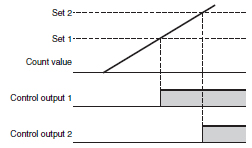

Control output patterns or display patterns that appear when counted up to the value set by the preset counter.

Examples:

Note: Refer to the description of each product for information on operation in other modes.

Number of preset values that correspond with the number of control outputs.

Example: Two-stage Counter

The maximum number of countable digits.

The type of element used to display the counting results.

LED: Light emitting diode

LCD: Liquid crystal display

Note: Electromagnetic counters display results using a revolving mechanism with printed characters.

Power supplied from the counter to sensors that are used for counting or resetting. (Also called sensor power.)

To restore the counting, display and output sections of the counter, to their initial states.

To reset the counter by cutting off the operating supply voltage.

To reset the counter by applying a specific signal to the reset input signal terminal.

To reset the counter automatically with a signal generated from inside the counter.

To reset the counter by a signal generated by internal circuitry.

To mechanically reset the counter by manual means.

To electromagnetically reset the counter by applying a reset signal.

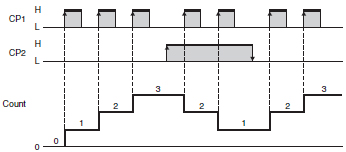

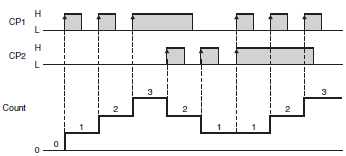

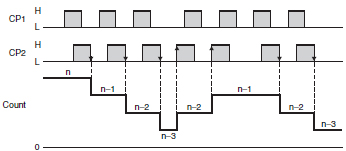

Refer to the following timing charts for the input modes of incremental, decrementing, and up/down (or reversible) Counters. (These charts focus on the up/down input mode.).

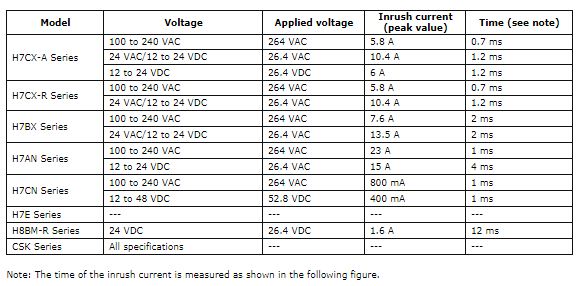

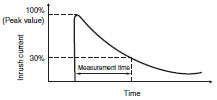

"---" indicates a constant current and therefore the corresponding values are omitted from the table. All the values are approximate values and should therefore only be used as a guide.