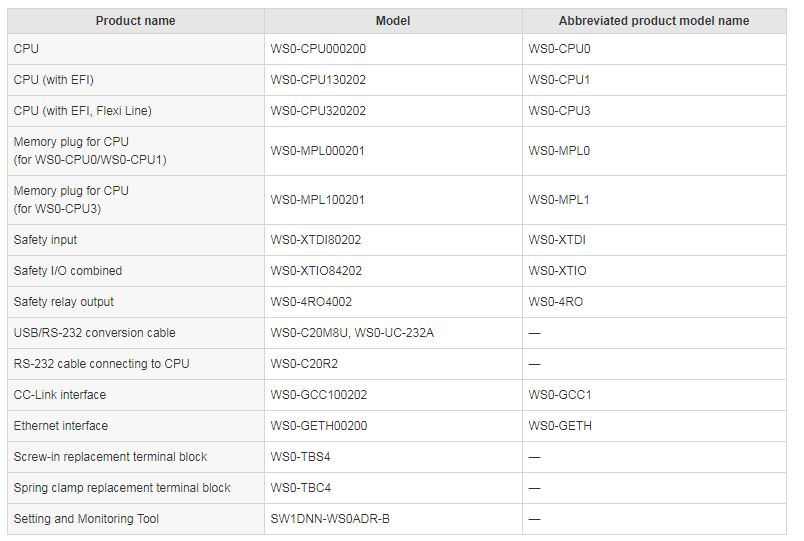

Safety controller MELSEC-WS Series

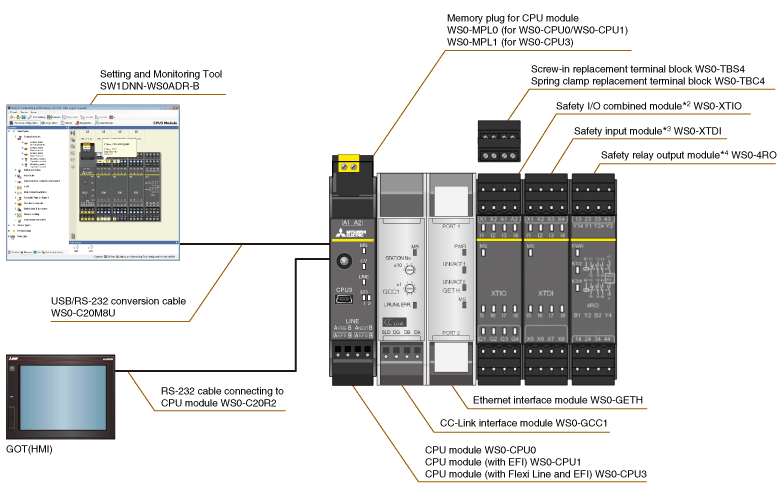

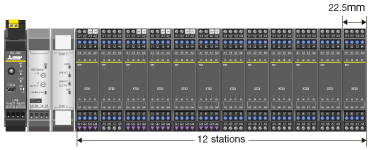

This compact safety controller complies with EN ISO 13849-1 Category 4/Ple and IEC 61508 SIL 3 safety standards. It is ideal for small to medium-scale safety control system. Safety I/O points can be extended to 144 points per CPU module according to the system configuration. Utilizing the dedicated setting and monitoring tool*1, setup and logic creation can be easily done.

MELSEC-WS Series system configuration

Flexible extensibility

Fast shut off function realizing a response time of 8 ms

Fast shut off function that enables the safety I/O module to shut off safety output without going through the CPU module realizes a response time of 8 ms. This system can shorten safety distances in the safety system.

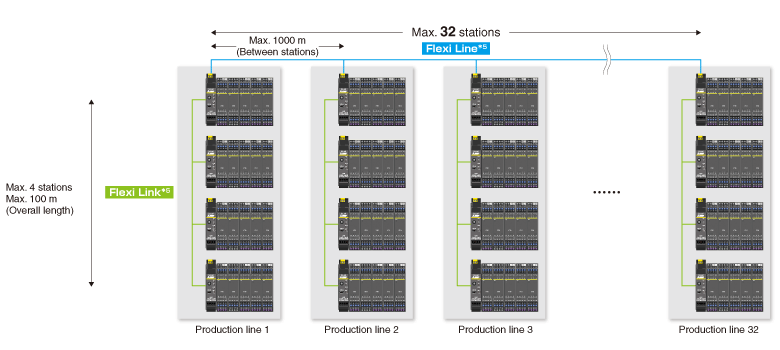

Flexi Line/Flexi Link

Safety communication network between safety controllers

Safety communications between safety controllers can be easily established at a low cost just by connecting the CPU modules with dedicated cables. Safety communication is realized without a dedicated network module, allowing utilization in various production site. In addition, coordination between multiple devices is possible, improving production system safety.

Safety control can be easily added to existing MELSEC PLCs (CC-Link/Ethernet)

Applicable functions with network interface

Connecting the safety controller to CC-Link, safety control can be performed with the existing MELSEC iQ-R/Q/L module. Furthermore, operation status and error status of the safety controller can be monitored with the existing MELSEC iQ-R/Q/L module. This helps quickly identifying the factor of emergency stop and faulty equipment.

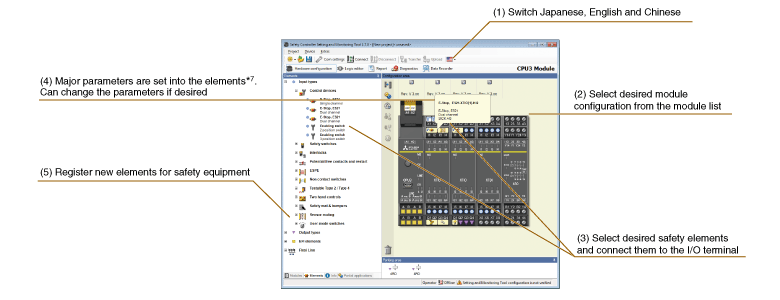

Dedicated "Setting and Monitoring Tool*6" provides intuitive system configuration environment

■ Configuration

Hardware configuration can be easily and quickly done using a wide range of elements.

Make settings simply by drag-and-drop decision. Elements for safety devices of mitsubishi's partners are also available. Please contact your local Mitsubishi representative.

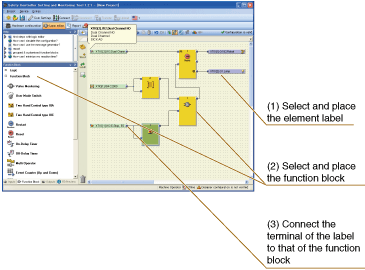

Logic Editor

Elements connected to the I/O terminal are automatically labeled, enabling logic creation easier using labels and function blocks.

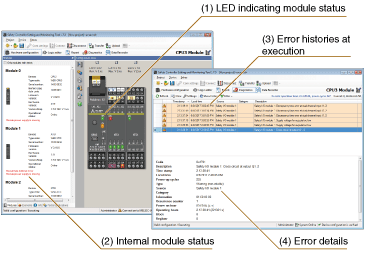

Diagnosis/monitor

Monitoring of the internal status of modules and error histories is possible.

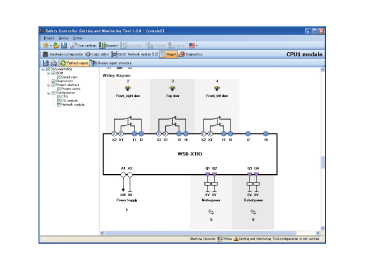

Report

The wiring diagram for I/O modules can be automatically created. Report such as error diagnosis can be created, printed, and saved as PDF.

I/O matrix

The relation of inputs and outputs can be displayed as a matrix.

ON/OFF status of safety input signal and safety output signal processed by the safety controller can be stored.*8 Results recorded on the Setting and Monitoring Tool can also be viewed on the computer to utilize for troubleshooting.

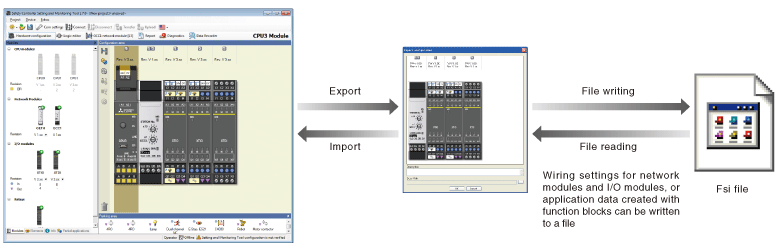

Import and export of logic

The connection settings to the I/O modules or application logic created with function blocks can be stored in a single setting file, and data can be read out of stored setting files.

| TITLE | DOCUMENT TYPE | SIZE |

| Mitsubishi Melsec WS Brochure | Catalog | 1042 KB |

|---|---|---|

| WS SAFETY | Manual | 2764 KB |