|

Lighting variations allow selection of optimal lighting conditionDPM is a process used to directly mark parts with product information. |

|

|

|

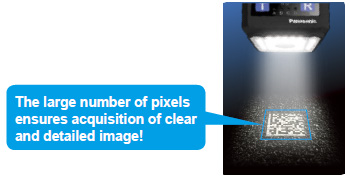

1.2-megapixel image sensor captures clear imageThe LP-ABR10 series code reader is equipped with a high-resolution, 1.2-megapixel CMOS image sensor. |

|

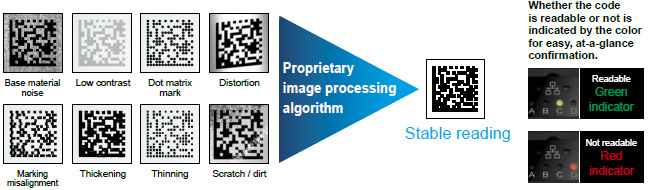

Proprietary algorithm maintains stable readingSince DPM codes are directly marked on parts, they can result in the generation of a large amount of noise due to surface irregularities or insufficient contrast against the background. |

|

|

The LP-ABR10 series code reader supports 2D code marking quality verification in compliance with ISO/IEC 15415 and AIM DPM-1-2006.

This enables management of 2D code marking quality using quality items in compliance with the international standards.

Management of changes in the 2D code marking quality is useful for preventive maintenance of production lines.

|

|

The auto teaching function automatically sets the most suitable 2D code reading condition. This function allows easy and convenient setting of optimal reading condition for various types of parts.

|

|

|

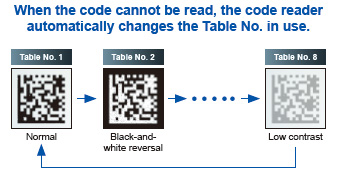

The code reader unit can be registered with up to eight sets of conditions. Even when 2D codes with different marking quality levels must be read, the setting automatically changes to an appropriate registered setting. This helps reduce the production line from stopping due to a read error. |

|

|

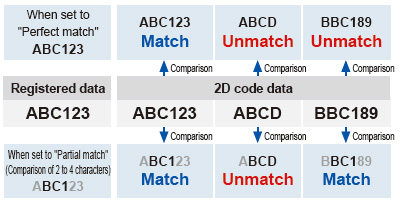

With this function enabled, the code reader compares the 2D code to read with preregistered data and reads it only when the 2D code matches the preset condition. The function has two types of setting, "Perfect match" and "Partial match." This function helps prevent defect products from mixing with good products. |

|

|

The code reader boasts an IP65 rating (IEC), and prevents entry of dust particles and resists the effect of water droplets. |

|

|

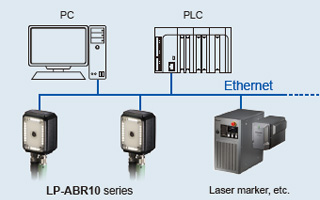

The Ethernet compatibility enables the transmission of not only the read data but also images and quality verification data. The LP-ABR10 series code reader is also equipped with a PLC link function for easy configuration of a network. |

|

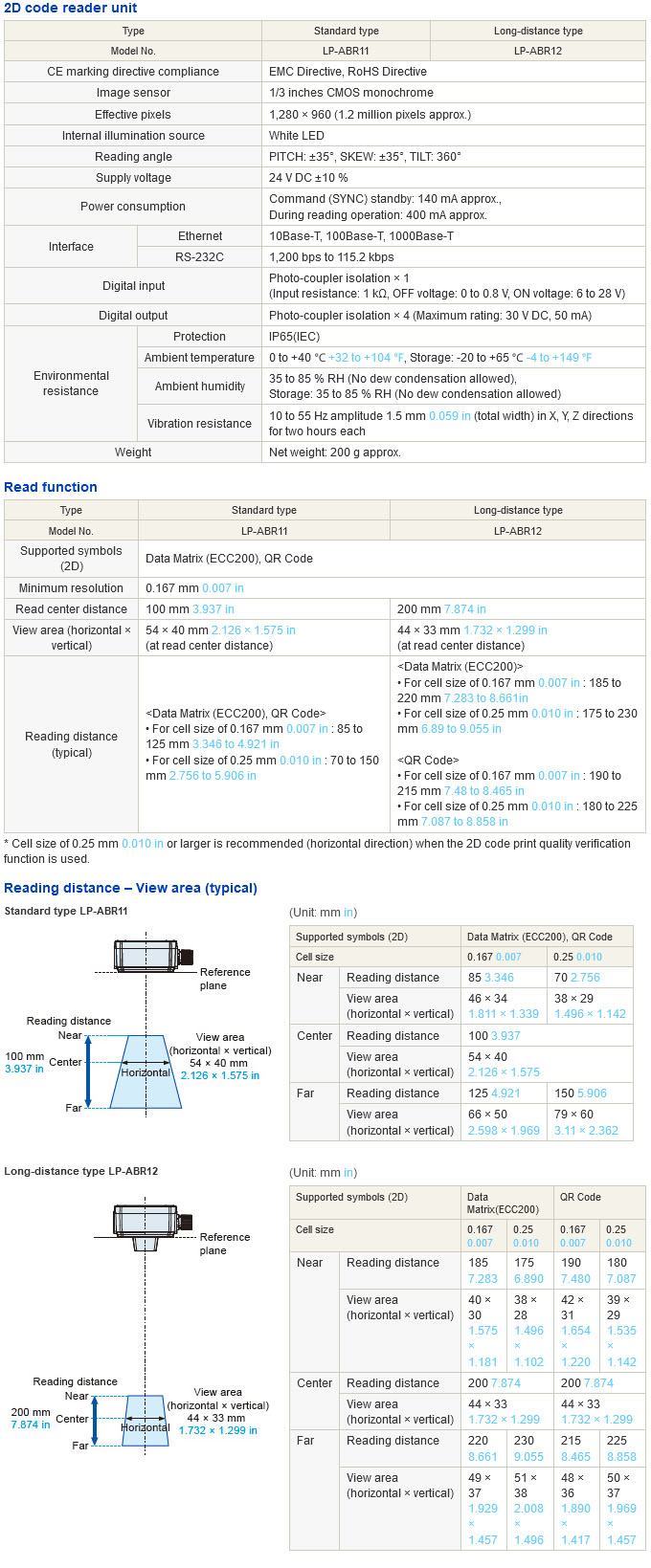

2D code reader

Standard type

|

2D code reader

Long-distance type

|

Control cable (sold separately)

|

LAN cable (sold separately)

|

| TITLE | DOCUMENT TYPE | SIZE |

| LP-ABR10 | Catalog | 3058 KB |

|---|---|---|

| Configurator LP-ABR Operation | Manual | 3062 KB |

| LP-ABR10 Series Setup / Operation | Manual | 1491 KB |

| LP-ABR Series Quick Reference | Manual | 1231 KB |