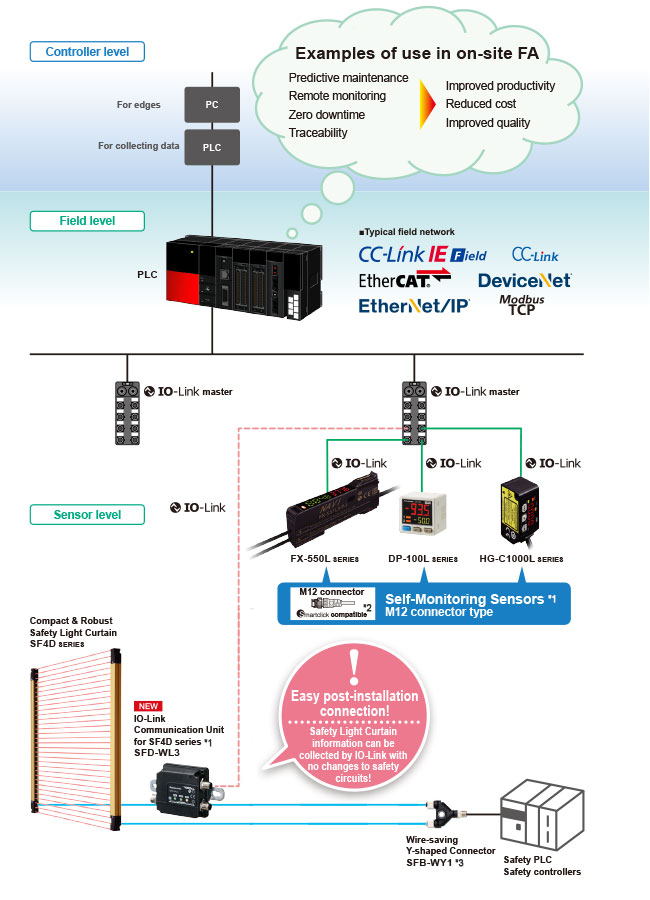

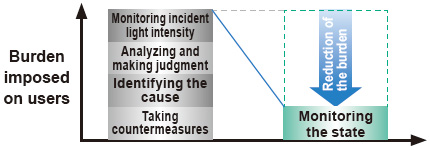

Field data collected and accumulated for “preventive maintenance” and “operation monitoring”.

An analysis of such field data requires high-level know-how and time, causing a burden to people

responsible for the production site management.

The Self-Monitoring Sensor manufactured by Panasonic is capable of reporting sensor data and its own state to the host device through the I/O Link master.

With the Self-Monitoring Sensor, you can immediately judge the state of the sensor and easily identify the cause of failure. Thus, this sensor contributes to the reduction of the burden experienced by the client in collecting and analyzing data.

|

||

|

| *1 | Can be connected to any manufacturer’s IO-Link master that supports various field networks. |

|---|---|

| *2 | Smartclick is a registered trademark of Omron Corporation. |

| *3 | Wire-saving Y-shaped connector SFB-WY1 is an option of the SF4D series. |

| *4 | IO-Link non-compatible devices (PNP output) that have digital input / output functions (ON/OFF signals) can also be connected. |

CC-Link IE Field and CC-Link are trademarks of Mitsubishi Electric Corporation, and are controlled by the CC-Link Partner Association.

DeviceNet and EtherNet/IP are registered trademarks of ODVA (Open DeviceNet Vender Association, Inc.).

EtherCAT is a registered trademark of Beckhoff Automation GmbH.

Modbus is a registered trademark of Schneider Automation, Inc.

|

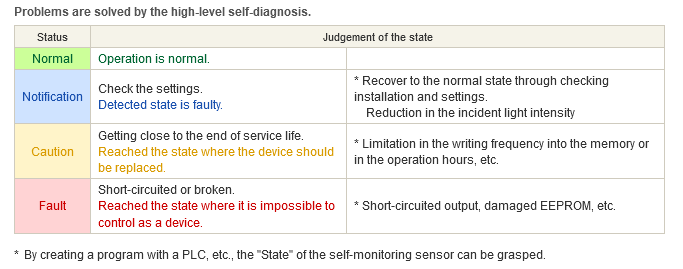

Problems are solved by the high-level self-diagnosis.

Easy use of IoT

|

“Predictive maintenance” can be easily achieved through monitoring the state of the Self-Monitoring Sensor. |

|

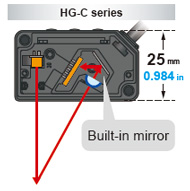

The HG-C series is the smallest CMOS laser sensor in industry *. W20 × H44 × D25 mm W0.787 × H1.732 × D0.984 in, 35 g approx. (without cable)

* As of May 2015, in-company survey.

|

A new optical system with a built-in mirror |

|

|

An aluminum die-cast casing protects from strain and heat |

|

|

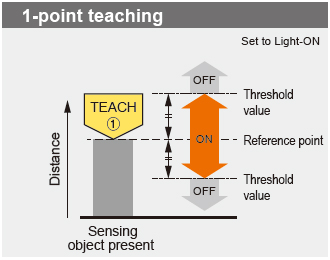

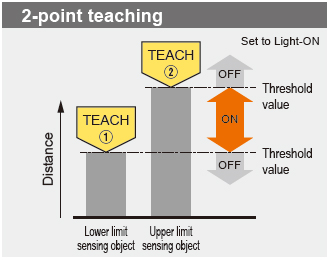

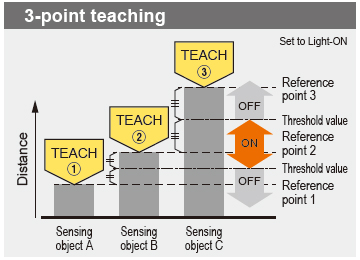

With an object below the sensor, press the TEACH key to set the valid range for distances via threshold values. There are 3 methods for setting the valid range: 1-point, 2-point, and 3-point teaching.

|

|

|

|

|

|

|

|

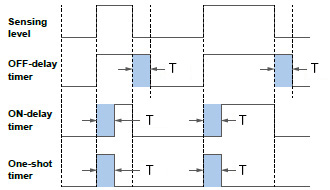

The time mode options are “off-delay timer,” “on-delay timer,” “one-shot timer” and “no timer.” The counting time is fixed to 5 ms.

|

Off-delay timer |

|

|

The peak hold function holds the maximum measured value which is output and displayed.

The bottom hold function holds the minimum measured value which is output and displayed.

* The peak hold function and the bottom hold function cannot be set at the same time.

* When the zero set function is executed while the peak hold function or the bottom hold function is valid, the held measurement value is reset.

Fine adjustment of threshold values can be performed while measurement is proceeding on the display, and even after teaching.

This function protects setting conditions from unintentional changes.

* For other functions and procedures for setting the functions, see“PRO Mode Setting”.

Sensor

|

Simple mounting bracket (Optional)

|

|

| TITLE | DOCUMENT TYPE | SIZE |

| FX-550L / DP-100L / HG-C1000L | Catalog | 3188 KB |

|---|---|---|

| HG-C / HG-C1000L | Catalog | 4706 KB |

| HG-C1000L INDEX LIST | Manual | 193 KB |

| HG-C1000L | Manual | 1407 KB |