|

|

|

On the bottom of the sensor are two detection units, one located at the front and one at the center. If a liquid leak occurs in front of the sensor, the front detection unit will detect even a small incipient leak. When the leak increases in volume and reaches the center of the sensor, it will be detected as an abnormal leak.

While previous implementations of two-stage liquid leak detection have relied on two separate sensors installed at different heights, the SQ4 delivers the same full-featured detection capability in a single sensor unit.

|

|

|

|

In addition to detecting liquid leaks, the SQ4 can detect both human error (such as a failure to install the sensor) and sensor malfunctions. If the sensor itself or the sensor and its mounting bracket have become dislodged, have been improperly installed, or are suffering from a broken cable connection, light from the emitter will not reach the receiver, causing the device to generate the same output as if a liquid leak had occurred.

|

|

|

The SQ4 can also be used without a controller, allowing the benefits of two-stage detection to be added to existing equipment by augmenting or replacing existing detection systems.

The SQ4 system is designed to fulfill safety requirements imposed by international standards. When used in combination, the SQ4-A sensor and SQ4-C11 controller meet category 4 / PLe / SIL3 requirements under ISO 13849-1:2006, which has been updated to add probability criteria to the existing risk evaluation system (in the control category), allowing the functional safety of programmable electronic control systems and related devices to be evaluated. The sensor fulfills control category 1 / PLc / SIL1 requirements when used in a standalone configuration.

*As of October 2010; according to research by Panasonic Industrial Devices SUNX.

|

The controller's two independent CPUs mutually check the unit's operating state, and redundant signal processing and output circuits ensure safety.

Failure mode and effects analysis (FMEA)* further increases operational safety.

|

|

The controller's safety input function can be used to connect wiring used to daisy-chain controllers together as well as input from safety contacts (2NC) on emergency stop switches, safety door switches, and other devices. In this way, safety output can be aggregated onto a single line to reduce safety circuit wiring and lower costs.

|

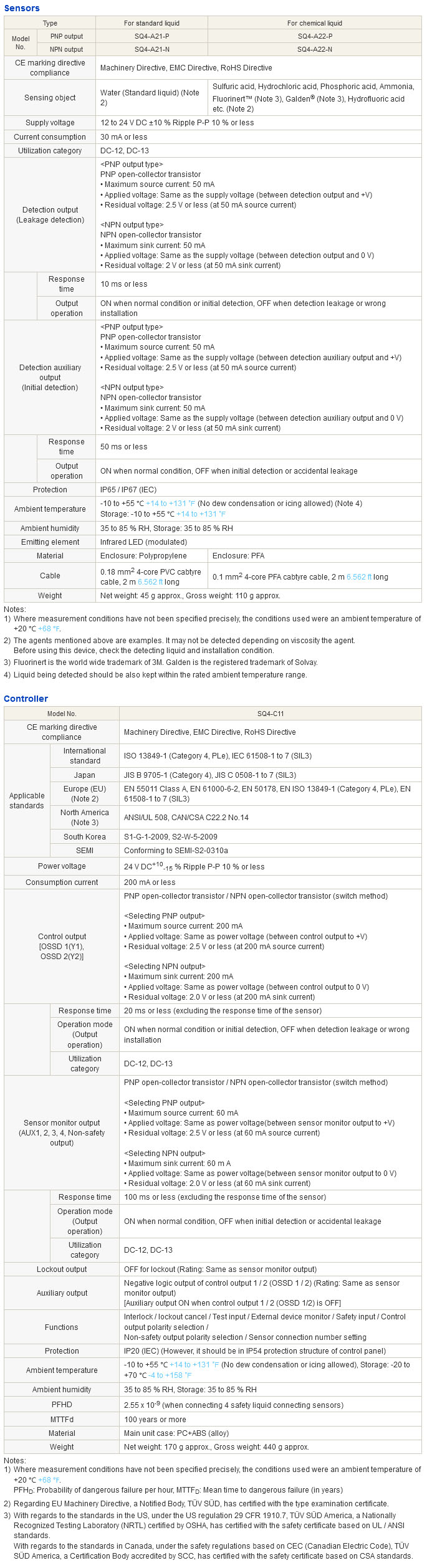

Sensor

|

|

Sensor

|

|

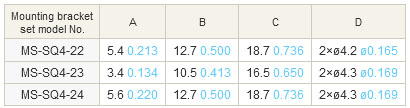

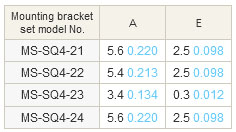

Mounting bracket set

|

Notes:

| 1) | Drawing above is for PFA mounting bracket. PVC mounting brackets do not incorporate stainless steel bushes. |

|---|---|

| 2) | The size of mounting holes of PVC mounting bracket is ø4.3 mm ø0.169 in |

Controller

|

| TITLE | DOCUMENT TYPE | SIZE |

| SQ4 | Catalog | 2636 KB |

|---|---|---|

| SQ4-A series | Manual | 577 KB |

| SQ4-C11 | Manual | 689 KB |

| CN-EP[Connector] | Manual | 73 KB |