MICROSITE CSS – DO NOT DELETE

OMRON introduces the LD-250, the latest addition to our LD series of autonomous mobile robots.

The LD-250 boasts a payload capacity of 250 kg and is compatible with most other LD accessories. The LD-250 allows customers to load larger and heavier payloads, making fewer trips with heavier batches, ultimately increasing return on investment. With the LD-250 in your fleet, you can do more with less equipment.

Features of LD250

1. Higher Payload and Sturdier Structure

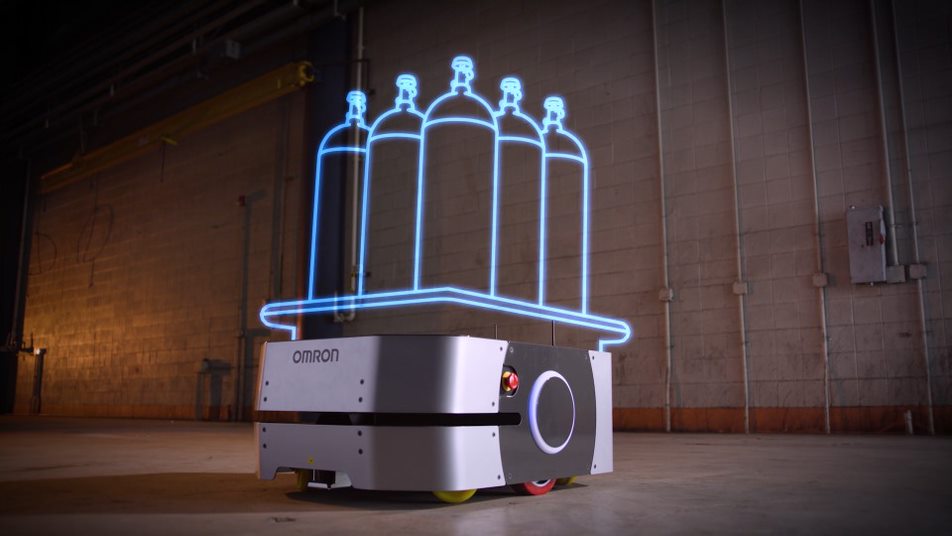

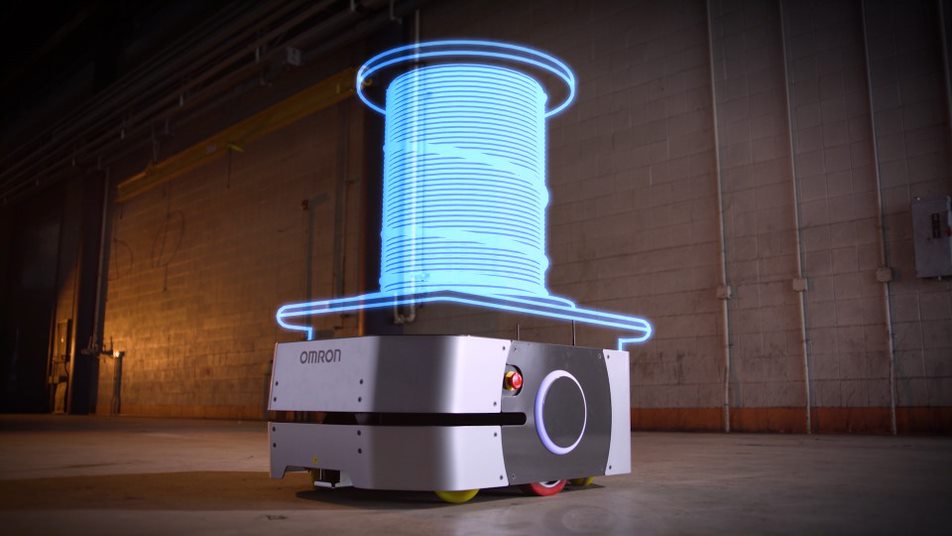

With a payload of 250kg, the LD-250 is built with sturdier metal skins that can withstand unintended impacts and more demanding duties. It can also automate the transportation of bulky materials that would traditionally be moved around by people using carts. These would include items such as transmission blocks, seats, or wire harnesses in the automotive industry, as well as voluminous packaging materials in the food and commodities industry.

2. Highly Mixed Fleet

OMRON doesn’t just supply robots; it provides total automation solutions. For automated material handling, this means optimizing fleet performance through our industry-leading Fleet Manager. With the LD-250, OMRON mobile fleets can be more diverse and still be controlled through the same system.

3. Faster ROI

The LD-250 allows customers to load more onto a mobile robot, making fewer trips with heavier batches, increasing the return on investment. Customers can mix and match LD models to create the most efficient and flexible material transport system possible.

4. Customizable

OMRON allows customers more options in terms of customizing autonomous material transportation systems. In addition to cart transporters, conveyor tops, and other potential integrations, the LD-250 can be used to create a solution that best meets your specific needs. Customers can also integrate the LD-250 and an OMRON TM collaborative robot to build a mobile manipulator that can be customised to meet any job functions.

Designed to meet the industry’s latest requirements, our mobile robots interact with people to promote a collaborative, safe working environment.

- Higher payload (up to 250kg)

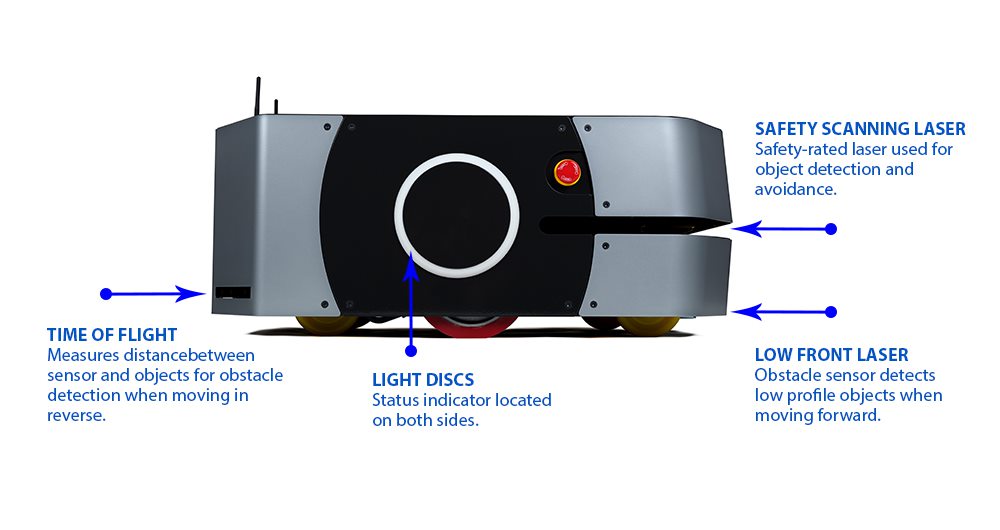

- New Time of Flight (TOF) rear sensor with higher resolution and wider field of view

- Brushed motors for higher torque

Yes. All accessories, including Acuity and HAPS, are compatible with the LD-250.

Approximately 13 hours unloaded, and 10 hours loaded.

ROI is estimated to be 6-18 months depending on region and application. While ROI depends largely on region (cost of labor), application, and overhead costs, it is reasonable to expect that the LD-250 will have a very attractive ROI.

We Love Using Technology to Make Lives Easier.

Talk to us today!