- 200 countries served

- We make plants safe on 5 continents

- Global network of service and support

OMRON - YOUR TRUSTED EXPERT IN MACHINE SAFEGUARDING

Creating A Safer Workplace,Without Compromising On Productivity

OMRON - YOUR TRUSTED EXPERT IN MACHINE SAFEGUARDING

Have you considered how safe is your workplace that uses machines with moving parts? There’s more to safety than simply installing a guard. If properly assessed and implemented, safety can enhance productivity and increase the company’s bottom line.

Did you know

Working With MachineryCan Cause Injuries & Productivity Loss?

Did you know

Working With MachineryCan Cause Injuries & Productivity Loss?

Are your workers fully protected against associated hazards and injuries from moving machinery?

From rotating shafts, shearing, to moving or stationary sharp edges, the mechanical motion of a machinery or equipment can expose the worker to risks such as entanglement, severing, cutting and puncturing.

Common Mechanical Hazards

- Rotating shafts and gears

- Shearing

- Cutting or puncturing

- Abrasion or friction

- Sharp edges

- Entanglement

Common non-mechanical hazards at a facility include heat, ionising radiation, and harmful chemical emissions. If not adequately managed, it can cause serious injury to the operator - such as burns, electrical shocks or chemical-related illness.

Common Non-Mechanical Hazards

- Dust

- High intensity light

- Explosives / Flammable

- Electrical shock

- Extreme heat

- Radiation

OVERCOMING INDUSTRY CHALLENGES

Discover How Machine Safety Can Impact Your Bottom LineOVERCOMING INDUSTRY CHALLENGES

Discover How Machine Safety Can Impact Your Bottom Line

Implementing proper machine safeguarding are paramount to plant owners and EH&S officers as it:

- Minimizes injury-related expenses

- Lowers absenteeism due to work injuries

- Increase productivity and quality of work

- Boosts workforce morale

- Reduces employee turnover

- Reduces liability for employers

- Showcases compliance with machine safety standards

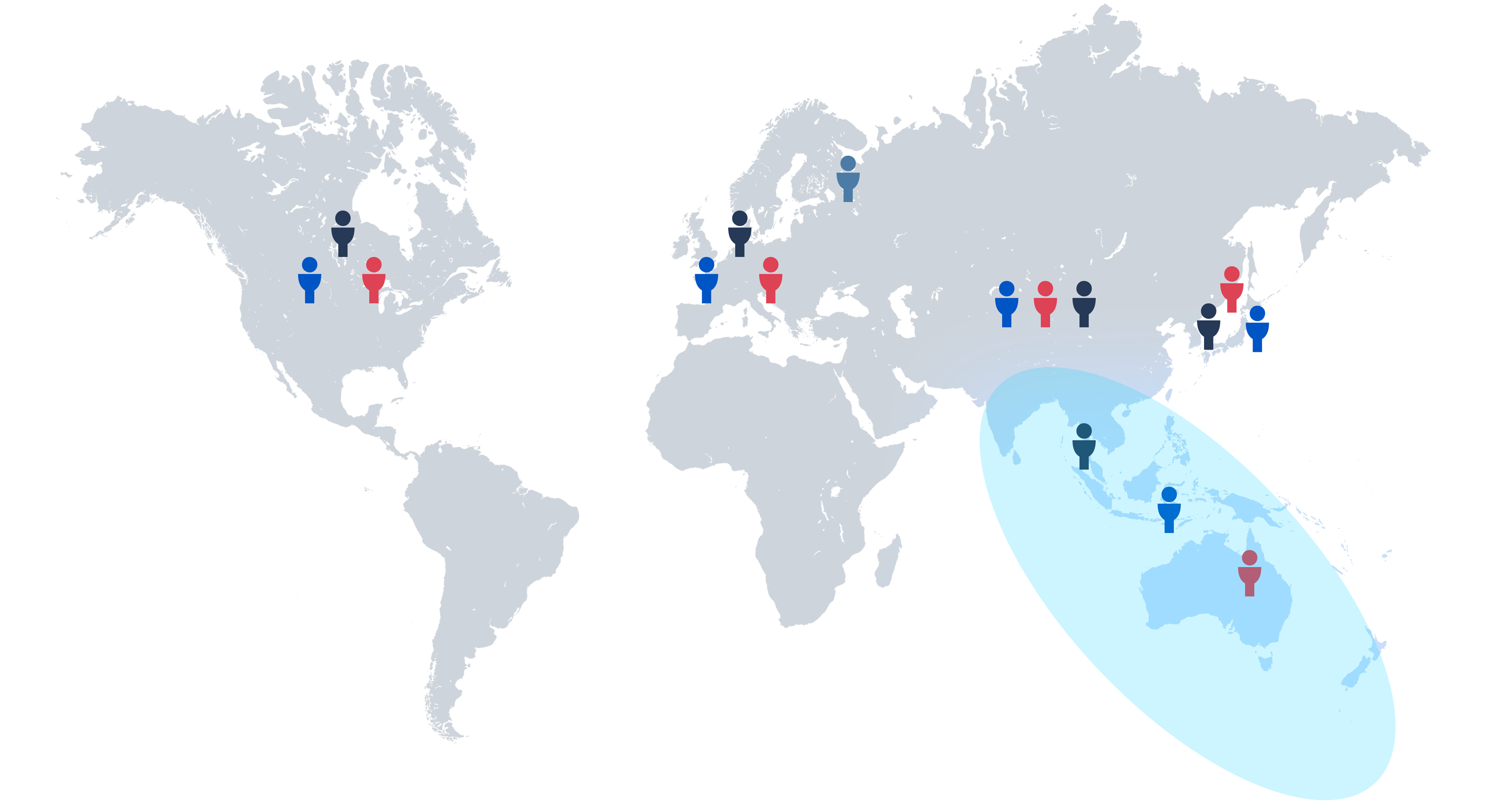

Global Support

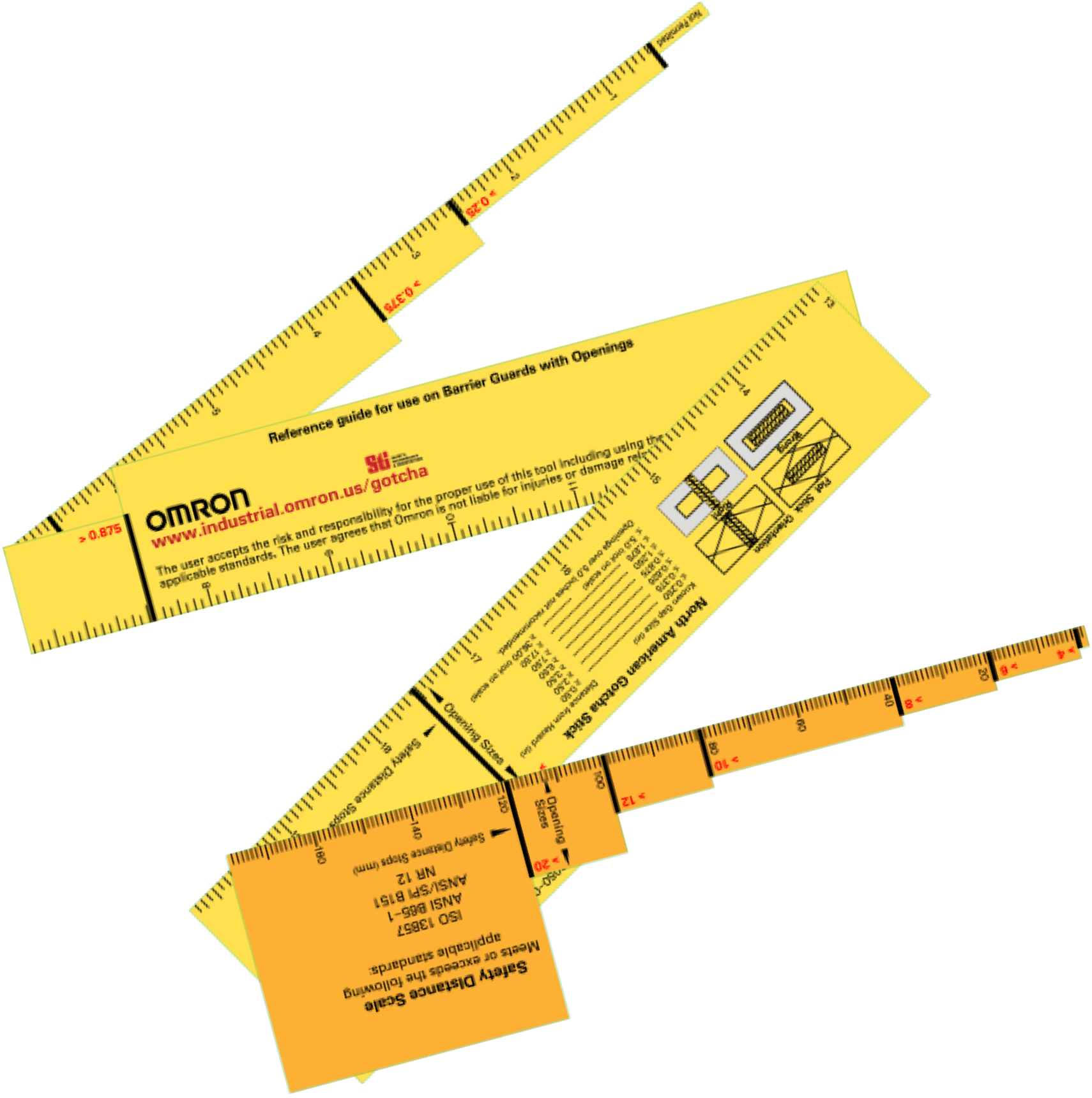

OMRON Advantage In Machine SafeguardingProtecting our workers from harm is a common industry goal, but machine safeguarding can often appear as daunting and intimidating. Leverage on our Machine Safeguarding Experts from a unique and competent global team serving 200 countries across a broad range of industries.

Our Global Footprint

Our safety commitment is supported by Safety Device Specialists, Safety Integration Team, and Safety Committee Members, located across the world. We work closely with a trusted team of Contracted Assessment / Engineering Partners to bring you the best machine safeguarding solution possible.

SERVING YOU

The Value We Deliver

OMRON Safety Solutions

With potential workplace hazards and a complex maze of standards and regulations, it can be difficult to navigate without the right expertise. Trust OMRON to help protect your workers against hazards and injury, while maintaining productivity and efficiency:

Safety Skill Builder Workshop

Injuries can occur when machines are used improperly due to inexperience or lack of training of the work personnel. Our team of TÜV Certified Functional Safety Engineers offers risk assessments and customized solutions for your machine, application or entire plant. We equipped your engineering and production team capable of understanding importance of machine safeguarding for new and existing machines.

Find out moreOMRON Safety Services

Our value as a safety partner goes well beyond our comprehensive range of world class products. We offer unmatched combination of expertise, products and services that enable us to help you find the best solution to safeguard your most valuable assets – your people – without compromising productivity.

Find out more