Meeting Market Demand

For Quality & Diversified Packaging Needs

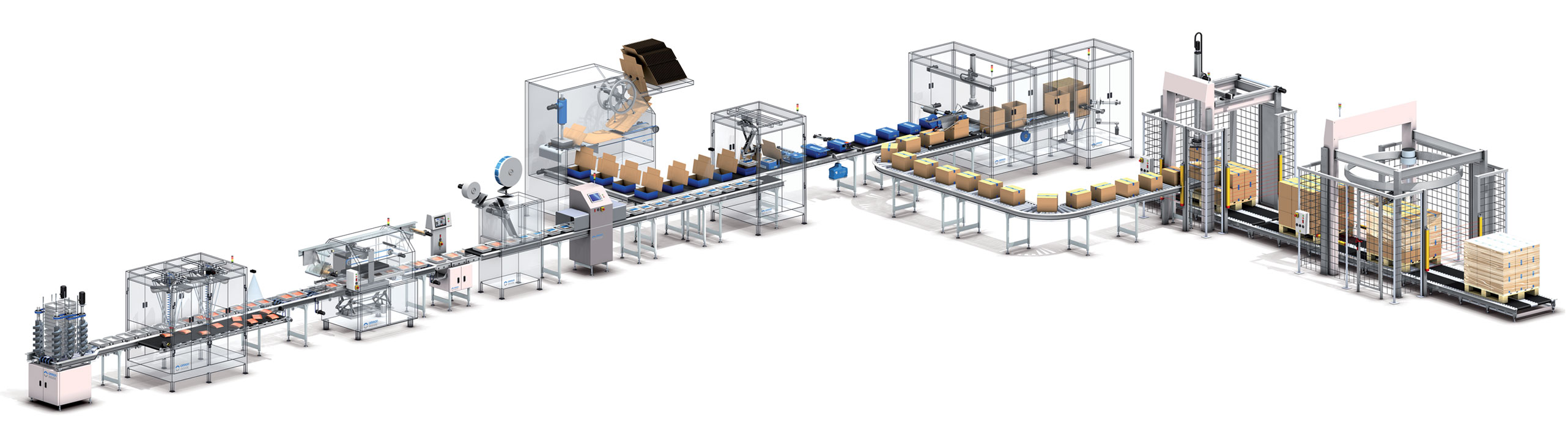

Today, as consumers are becoming more sophisticated in their tastes, manufacturers need to continuously come up with diversified packaging to attract consumers.

Delivering high quality and diversified packaging is vital for the sales bottom line, especially in competitive food and retail markets.

Challenges Faced By OEMs and

Manufacturers in Today's Market

In the past, packaging plants run on one product per line with fixed parameters set (e.g. product size and weight). The shift in consumer demands today has created new challenges for OEM (Original Equipment Manufacturers) and manufacturers.

There is a critical need for OEMs to build quality machines that allow manufacturers to run multiple products per line and in different pack formats, while ensuring that quality is not compromised.

OEMs

The challenge of achieving shorter machine-building time, while keeping cost low and maximising operational efficiency.

Manufacturers

The challenge of achieving fast and cost-effective product changeovers with shorter production time.

How We Can Help OEMs

3 Key Benefits For OEMs

As today's world calls for multiple products per line, OMRON Packaging Solutions are designed to bring three key benefits to OEMs. Discover how we can help you fulfil your promise to your customers, i.e. manufacturers.

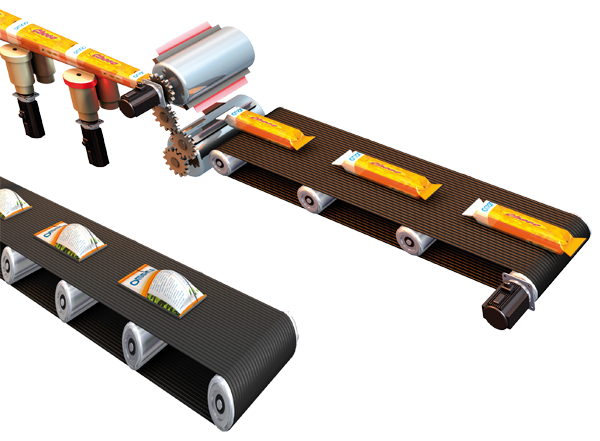

Quality Machines

Having errors in the filling, cutting or sealing process can result in defective packages and wastage. As such, having reliable solutions to maximise the machine performance is essential to reduce operational risk and maximise cost savings.

Learn how our solutions can help you achieve accuracy in filling, sealing, and cutting.

Discover more

Manufacturing Efficiency

With increasing consumer demands in diversified packaging (e.g. in different pack formats), frequent changeovers may impact the efficiency of conventional packaging process, as more downtime may be spent on reconfiguration during recipe changes.

Learn how to build machines that promote easy and reliable changeovers for increasing productivity in packaging process.

Discover more

Design Efficiency With

SYSMAC Studio Software

Designed to effectively shorten development time, the SYSMAC Studio is an easy-to-use software that provides an integrated environment for setting, programming, and debugging machine automation controllers.

Learn how it can help you accelerate machine design in a shorter time.

Discover moreIs your team interested in empowering your customers

with our latest packaging solutions? We can help.