Reduce Downtime in Your

Car Production Process Flow

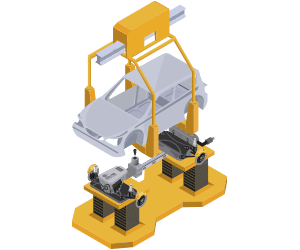

In any car manufacturing setting, the process flow is usually made up of various steps:

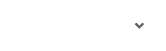

PRESS SHOP

Aluminium and steel sheets are moulded by high-tech servo presses to produce car parts such as side frames, doors, hoods and roofs.

WELDING SHOP

The overall car framework is put together by welding and joining techniques handled by high-precision robots.

PAINT SHOP

The finished car framework is cleaned and treated for lasting corrosion protection before coats of paint are applied by high-tech robots.

ASSEMBLY SHOP

In this final step, the drive unit of axles, transmission, engine and exhaust system and the car framework are fitted together to form the finished product.

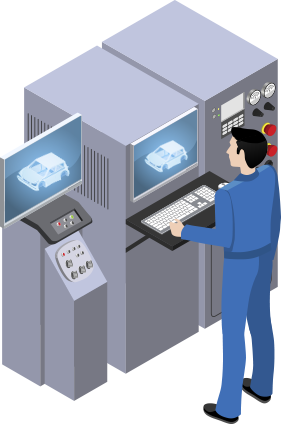

OMRON Industrial Automation Scanner MS-890

Before a car body is moved from one shop to the next, the barcode affixed on the car framework is scanned to pre-empt the next shop of its readiness for the next stage of production.

With the massive flow of information exchange between the shops, the accurate scanning of barcodes is therefore an important practice. This ensures seamless communication of information between the shops which in turn, is crucial for production flow to run smoothly.

Discover how OMRON Industrial Automation Scanner MS-890 can help you reduce your production downtown and improve overall productivity.

Challenges of Scanning

With the massive amounts of information being shared between each shop, communication breakdown may occur when the scanning of barcodes becomes problematic along the production flow. This may result in major delays and downtime in production when unfinished car bodies have to be pulled from production, ultimately leading to a loss in productivity.

The key to avoiding these issues is through achieving seamless communication, where barcodes are scanned accurately.

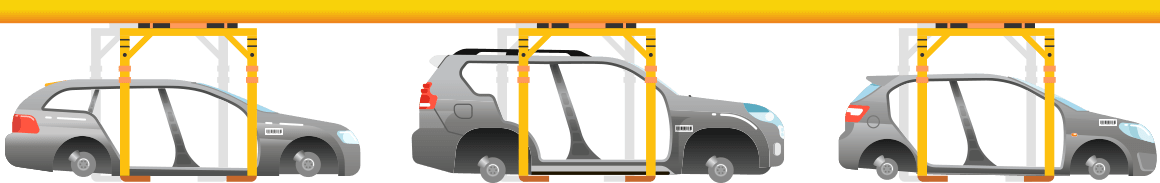

Inability to scan inconsistently-placed barcodes due to manual method of pasting the labels.

Inability to scan inconsistently-placed barcodes due to manual method of pasting the labels.

SOLUTIONMS-890 features a Sweeping Raster that allows large scanning zones. This ensures that barcodes pasted within the scan zone will be read.

MS-890 features a Sweeping Raster that allows large scanning zones. This ensures that barcodes pasted within the scan zone will be read.

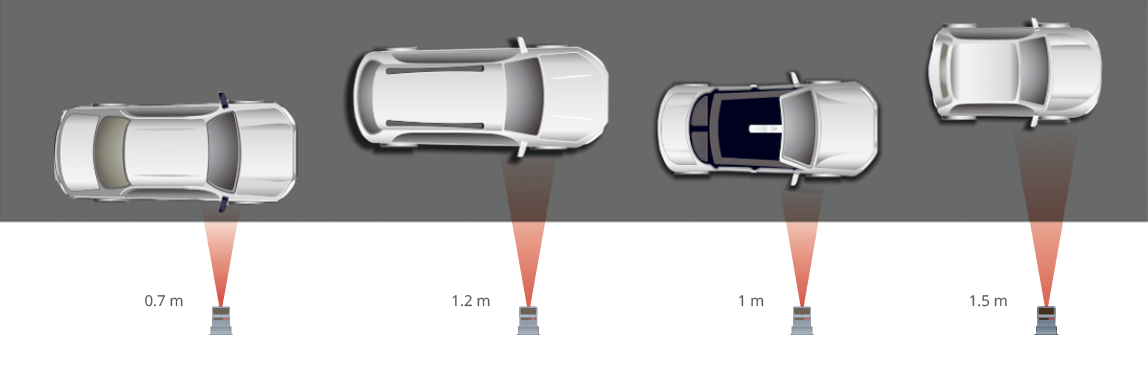

Inability to scan long and variable distances on different car models of different sizes on the same production line

Inability to scan long and variable distances on different car models of different sizes on the same production line

SOLUTIONMS-890 offers a large depth of view and long read range of up to 3 metres. This ensures readability of all barcodes.

MS-890 offers a large depth of view and long read range of up to 3 metres. This ensures readability of all barcodes.

The capability of OMRON Industrial Automation Scanner to perform barcode readings from long, variable distances and wide angles on different car models makes it one of the simple and unique solutions for any car maker.

Enjoy

Would you like to achieve greater efficiency and

cost savings for your car manufacturing process?