STABLE DETECTION OF PACKAGING

WHEN LOT CHANGES

With increasing diversified product packages, there are cases where the packaging colors differs

from lot to lot. This may result in false detection. OMRON brings innovation to manufacturing sites

through automation with "integrated," "intelligent", and "interactive" concepts with our new color mark sensors.

Challenges Faced When Packaging

Color Varies From Lot To Lot

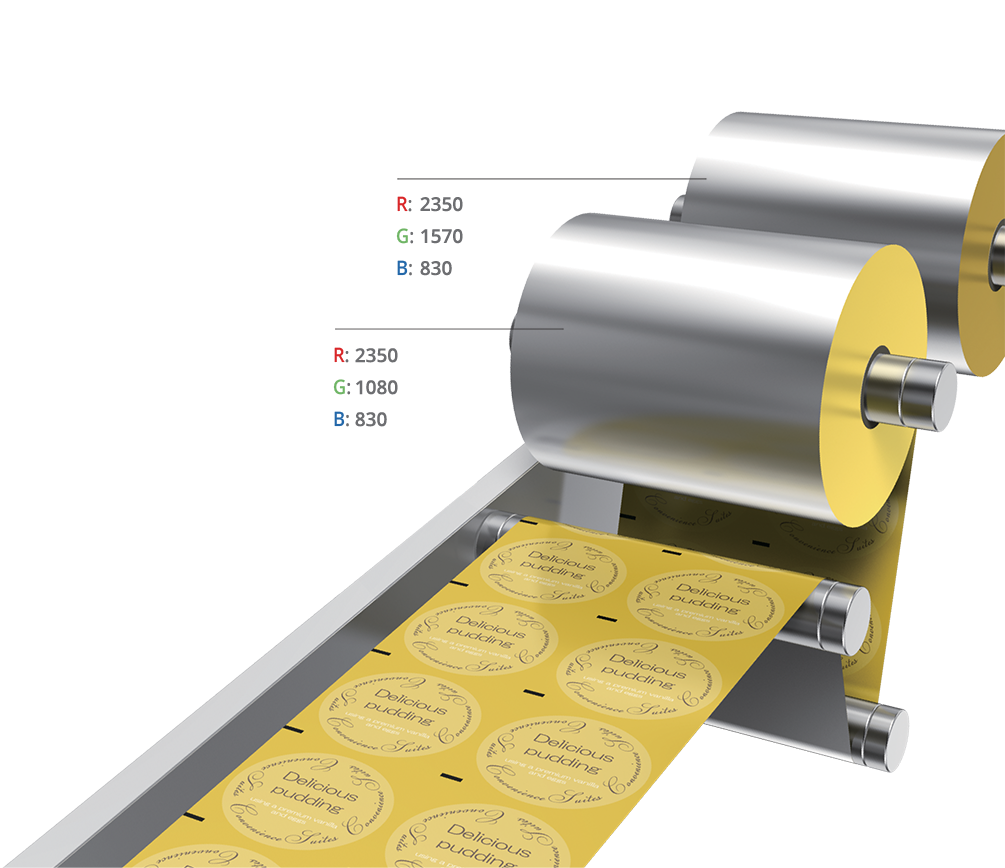

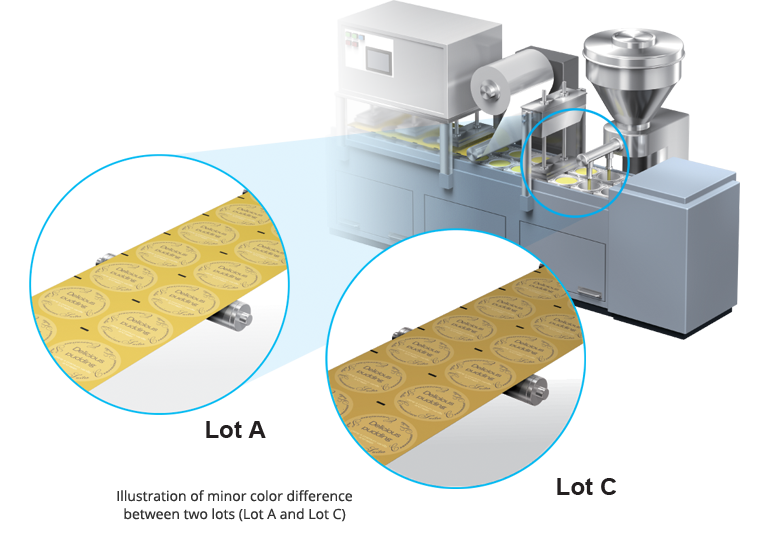

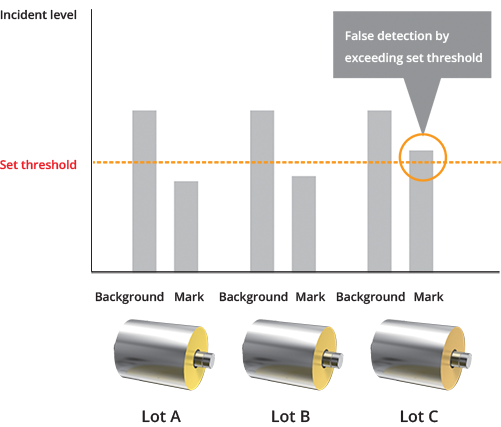

In cases where the colors of packaging materials vary from lot to lot,

false detection of color mark could occur if parameters are not adjusted. This could lead to

equipment stoppage.

In such cases, it can be difficult to determine the root cause, resulting in

decreased productivity and time lost from troubleshooting.

Color Mark

Photoelectric Sensor

(E3S-DC)

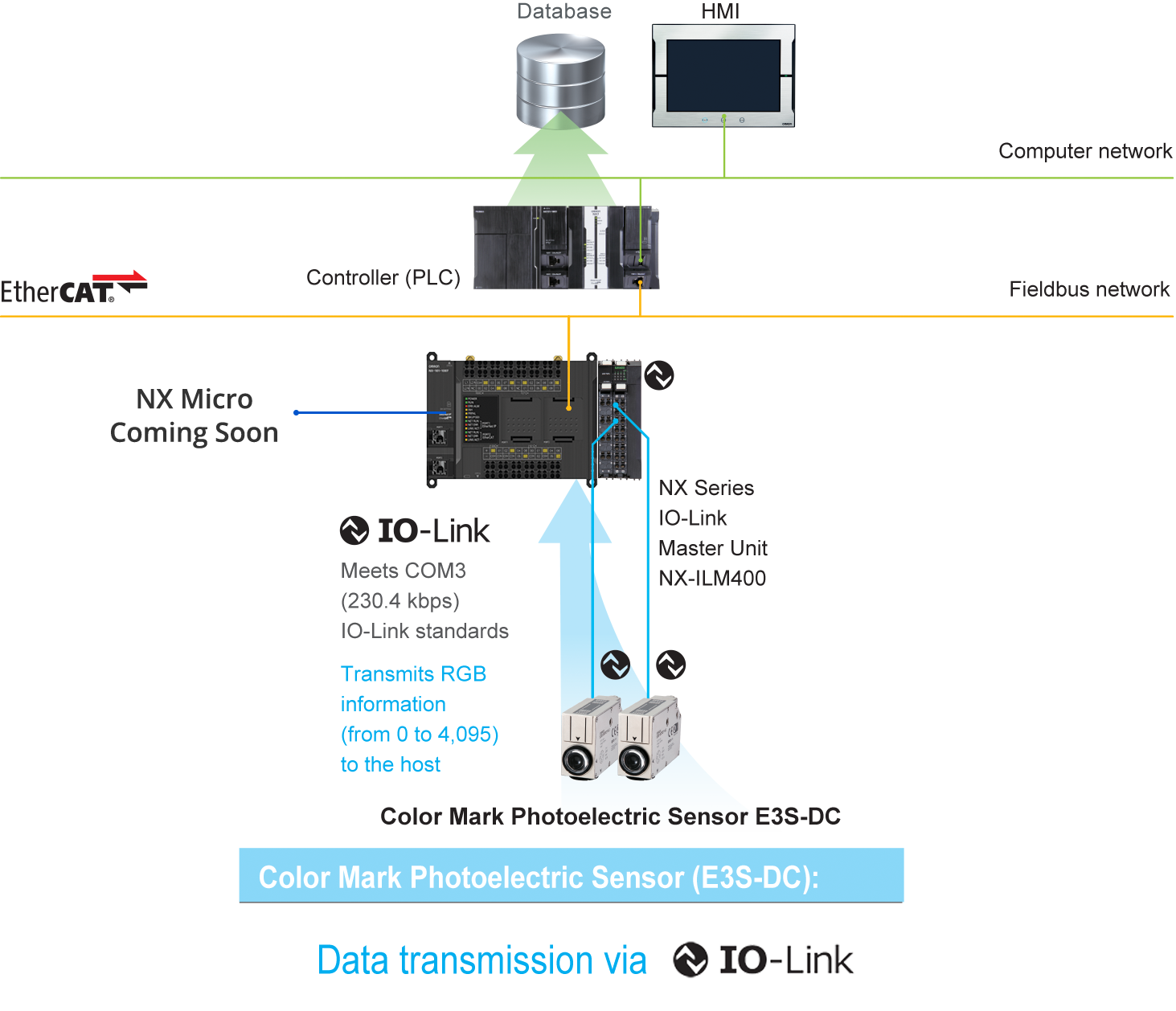

Visualization Of Color Variation

Via RGB Data Transmission Function

1

RGB Data Transmission Function

RGB information for color marks and backgrounds of each lot is transmitted to a host to be deciphered.

This information is then managed with a database, making it possible to set optimal thresholds and identify causes quickly if a problem arises.

RGB information for color marks and backgrounds of each lot is transmitted to a host to be deciphered.

This information is then managed with a database, making it possible to set optimal thresholds and identify causes quickly if a problem arises.

Previously, setting threshold during commissioning required the involvement of a technical expert.

With the data transmission function, optimal setting is achieved simply by registering the RGB

ratio of a packaging.

When the sensor makes a false detection, values can be easily checked to determine if the reading

error is due to the color variation in lot changes. This makes it easier to troubleshoot and

resolve such error.

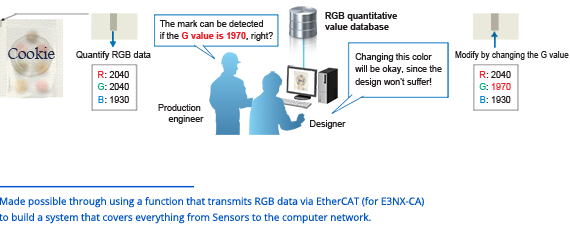

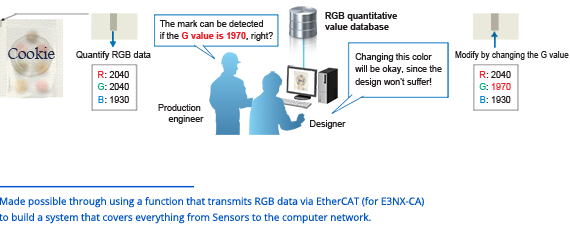

2

Test Parameter Support Function

The test parameter support function allows users to determine whether accurate detection is

possible for packaging designs in the prototyping stage.

Package designers and production engineers are able to use quantified RGB digital data to discuss

the designs. This allows them to reach a quick decision on which design to use, shortening lead time

from design to production line commissioning.

Color Fiber

Amplifier Unit

(E3NX-CA)

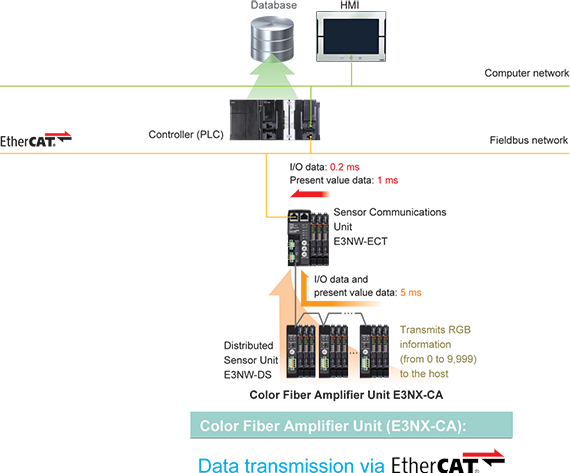

Visualization Of Color Variation

Via RGB Data Transmission Function

1

RGB Data Transmission Function

RGB information for color marks and backgrounds of each lot is transmitted to a host to be deciphered.

This information is then managed with a database, making it possible to set optimal thresholds and identify causes quickly if a problem arises.

RGB information for color marks and backgrounds of each lot is transmitted to a host to be deciphered.

This information is then managed with a database, making it possible to set optimal thresholds and identify causes quickly if a problem arises.

Previously, setting threshold during commissioning required the involvement of a technical expert.

With the data transmission function, optimal setting is achieved simply by registering the RGB

ratio of a packaging.

When the sensor makes a false detection, values can be easily checked to determine if the reading

error is due to the color variation in lot changes. This makes it easier to troubleshoot and

resolve such error.

2

Test Parameter Support Function

The test parameter support function allows users to determine whether accurate detection is

possible for packaging designs in the prototyping stage.

Package designers and production engineers are able to use quantified RGB digital data to discuss

the designs. This allows them to reach a quick decision on which design to use, shortening lead time

from design to production line commissioning.

Would you like to cut costly and painful downtime of locating faulty sensors in a large plant?

Download Our Brochure Get In Touch