Consumer demand is driving automakers to continuously produce safer and more efficient products. As a result of this automakers are constantly striving to achieve a target of zero defective parts in every batch produced. This goal can only be achieved by putting in place a system capable of total traceability, a system capable of back tracing every step of the manufacturing process, specifically the quality assurance and specification data.

Currently, computers are key for transferring data from the manufacturing site to the main server. This requires a major investment of time, effort and resources to implement as they need to integrate various quality inspection devices such as Vision, Profile and Measurement Sensor’s data as well as RFID information. For this, they need an IT specialist to work on the required software and an instrumentation specialist to oversee the necessary equipment. The biggest challenge is not just the in-depth understanding required for integration and maintenance, but also the cooperation needed between the two departments. Other elements which must be considered are software upgrades, antivirus and developments in hardware.

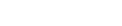

With the Omron SYSMAC platform, we offer seamless integration with your main server without needing to worry about the various points of integration with computers. SYSMAC can enable the easy integration, control of Vision and Smart Measuring Sensors along with Temperature Controllers, RFID code readers and 3rd-party devices such as Nut Runners. All of this results in easier and lower maintenance which can be done remotely, ultimately reducing the Total Cost of Ownership (TCO).

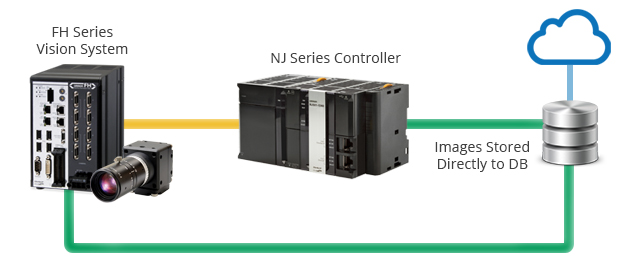

SYSMAC allows seamless integration with Vision Measuring Systems, enabling the user to save not only inspection results but also images of each component to the main database server without any additional hardware or software.

|

|

|

|

version 1.07 or higher supports the FH Series |

Machine Automation Controller |

Vision System |