Easy setup. Low Maintenance.

Consumer demand is driving automakers to continuously produce safer and more efficient

products. As a result of this automakers are constantly striving to achieve a target of

zero defective parts in every batch produced. This goal can only be achieved by putting

in place a system capable of total traceability, a system capable of back tracing every

step of the manufacturing process, specifically the quality assurance and specification

data.

Currently, computers are key for transferring data from the manufacturing site to the

main server. This requires a major investment of time, effort and resources to implement

as they need to integrate various quality inspection devices such as Vision, Profile and

Measurement Sensor’s data as well as RFID information. For this, they need an IT

specialist to work on the required software and an instrumentation specialist to oversee

the necessary equipment. The biggest challenge is not just the in-depth understanding

required for integration and maintenance, but also the cooperation needed between the

two departments. Other elements which must be considered are software upgrades,

antivirus and developments in hardware.

Reading of Direct

Part Marking (DPM) with code verification and recording to DB directly via

SYSMAC Controller

|

Part ID Code Read

before assembly

|

Final Assembly

Inspection

|

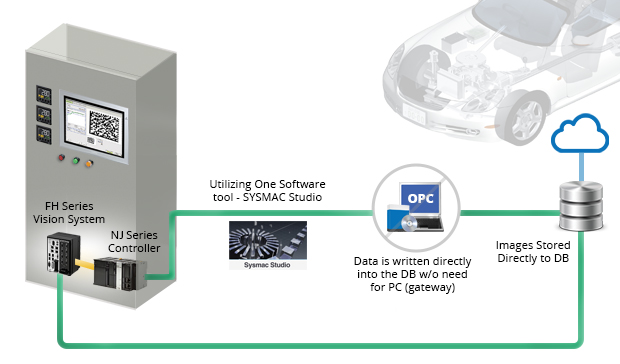

With the Omron SYSMAC platform, we offer seamless integration with your main server

without needing to worry about the various points of integration with computers. SYSMAC

can enable the easy integration, control of Vision and Smart Measuring Sensors along

with Temperature Controllers, RFID code readers and 3rd-party devices such as Nut

Runners. All of this results in easier and lower maintenance which can be done remotely,

ultimately reducing the Total Cost of Ownership (TCO).

Improved Quality & Parts Tracking

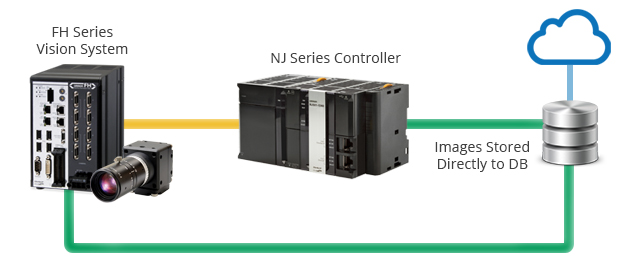

SYSMAC allows seamless integration with Vision Measuring Systems, enabling the user to

save not only inspection results but also images of each component to the main database

server without any additional hardware or software.

Detect

presence of Grading Dot and verified with Server

|

Capture

all tyres produced (Model & Serial no.) before sending it to storage

|

Meeting Industry Needs for SECS/GEM Protocol & Serial

Number Verification

Semi-conductor manufacturers are required to meet the standards set by the SEMI

(Semiconductor Equipment and Materials International) organisation, and those standards

are known as SECS (SEMI Equipment Communications Standard) /GEM (Generic Equipment

Model).

The Omron NJ series MAC is the first in the market to support the SECS/GEM protocol, this

creates the opportunity for manufacturers and OEMs alike, to design new machines based

on Omron's SYSMAC solution to conform to industry standards. The Omron SYSMAC solution

allows easy integration with motion control, HMI, safety, sensors, quality inspection

(vision system) while also implementing traceability and serial number verification with

the machine.

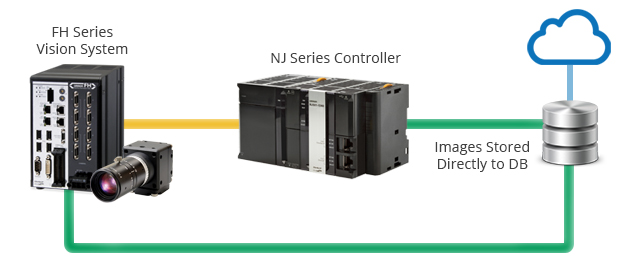

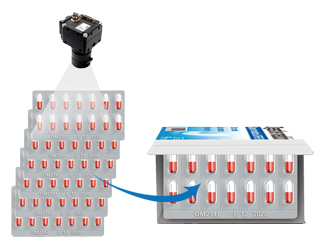

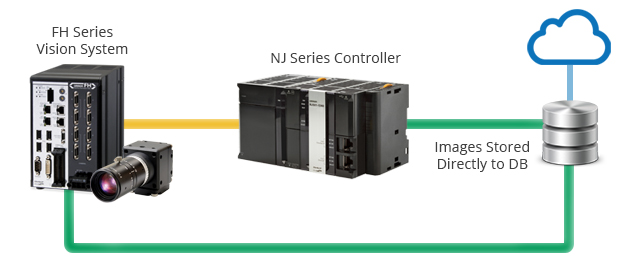

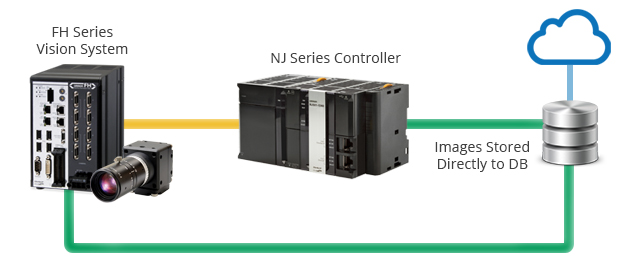

The diagram below shows a typical example of how the SYSMAC solution, using NJ with an FH

Series Vision System performing an inspection with traceability without the need for a

PC.

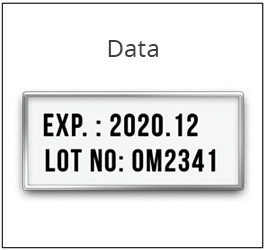

Capture

Serial no. with OCR and record to DB directly via NJ MAC

|

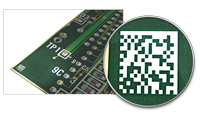

Decode

by FH and SYSMAC Controller verify PCB serial no. with DB

|

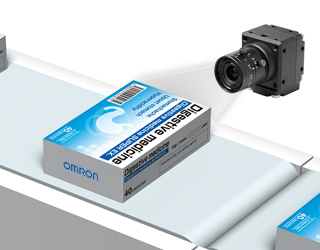

Package

Visual (Quality) Inspection

|

Complete Dataset for Seamless Tracking

With increasing demands on food safety and 'track and trace' in pharmaceutical products,

traceability combined with big data is becoming an important function in modern

production today. Quality improvements to products through vision inspection and expiry

date extraction verification with database can also be achieved with the use of

traceability. Improvements on productivity can also be made by monitoring production

status and data via mobile devices from anywhere in the world with database

connectivity. Downtime can be reduced while troubleshooting and simple production

analysis can be made on the database server instead of a gateway PC.

With Omron's traceability solutions you can achieve quality improvements and enjoy a

peace of mind for you and your customers.

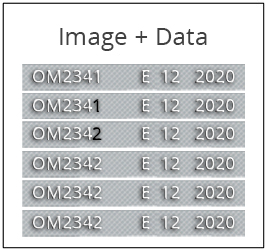

Data set of different variables (Image + Data) can be captured

and stored as one data set