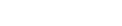

Fast Liquid Stabilization

Current Issue

Wait Times For Liquid Stabilization

Slow Down Production

Unlike solid components, transporting liquid must be done at a slower speed as it induces sloshing inside the packaging. It takes time for the liquid to stabilize before it can be further processed.

Having shorter transportation time would cause unwanted sloshing. Splashing on packaging seal, for example, may cause sealing failure. Sloshing may also influence the accuracy of a weighing process (e.g. for determining the correct content of pharmaceutical products).

Business Value

Anti-Sloshing Control Opens Up

Significant Productivity Gains

The key to increase production speed is to control unwanted movement when liquid is being transported, so the resulting wait time until the sloshing stops will be shorter.

OMRON vibration suppression technology enables you to run your liquid-handling machines at a faster speed, with significantly less sloshing motion. Speed up your production cycle without risking spillage that can compromise your throughput.

Our Technology

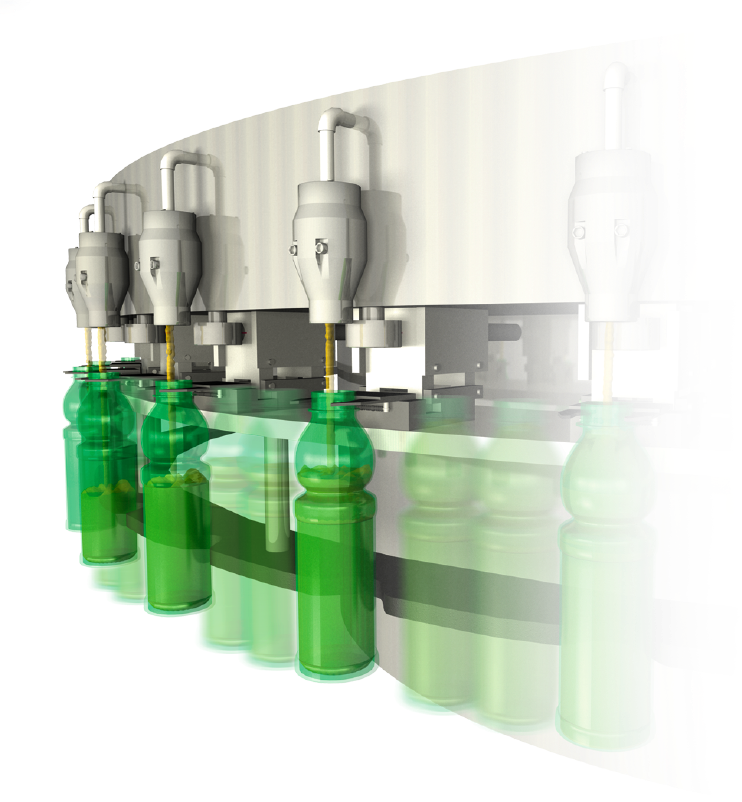

Speed Up Waiting Time

For Liquid Stabilization By 20%

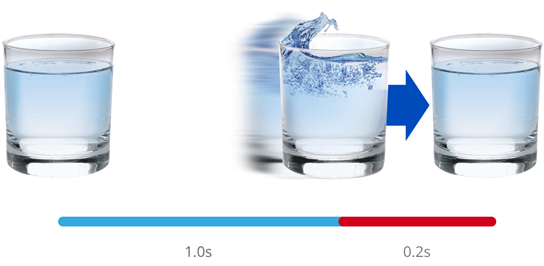

Without OMRON Vibration Suppression Technology

OMRON vibration control technology prevents liquid surfaces from sloshing through the use of sloshing suppression control. Handling speed can thus be increased, and waiting times are reduced by 20%.

This is made possible by OMRON NJ Controller’s Function Blocks. Function Blocks are predefined programs that shorten the time for liquid to stabilize, so the next process (e.g. measuring or sealing) can happen sooner. End users only need to input basic parameters on the central system and the program will take care of the complex calculation for optimizing the process.