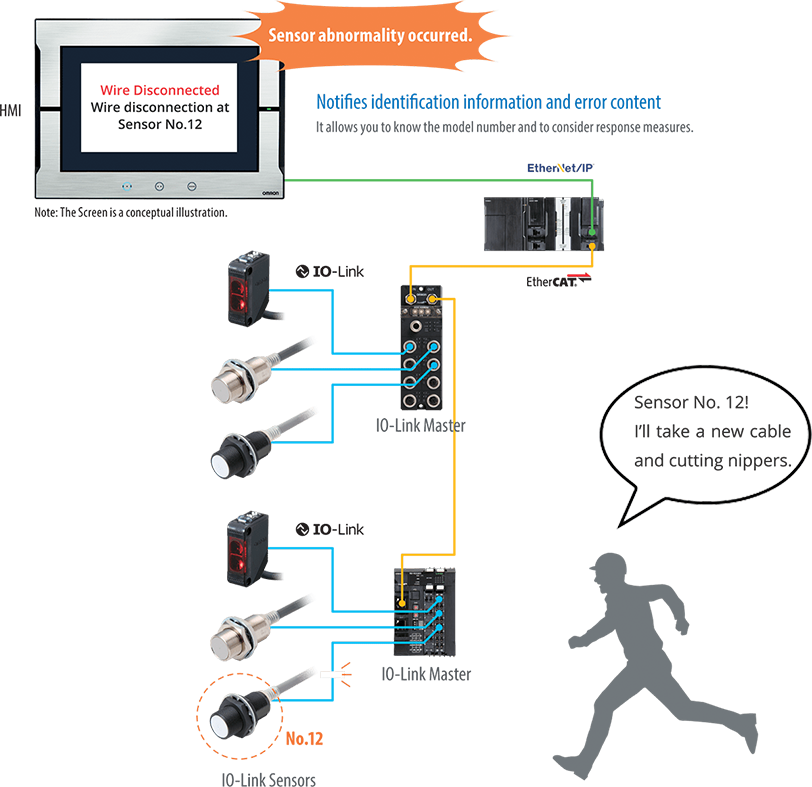

How It Works

When an abnormality occurs, the area and phenomenon is picked up by the IO-Link sensors. The exact location and factors for the abnormality is communicated back instantaneously to the maintenance engineer.

Shortest Recovery

As such, he can take the necessary replacement parts and head to where the abnormality occurred and recover the equipment in the shortest time. This works also with wire disconnection detection, both output wires and power lines.