Automotive Challenges

The automotive industry is shifting towards globalized platforms and standardised vehicle architectures. While this streamlines production, a single flawed part will result in broader, more detrimental effects to the supply chain. A reliable Traceability system can minimise these problems.

In 2014, 19 different automakers conducted what NHTSA has called "the largest and most complex safety recall in U.S. history." to address defective air bag inflators made by Takata Corporation, costing them $1 billion.

In 2016 Volkswagen had to recall over 11 million cars worldwide due to a non-compliance emissions control system. This resulted in a $14.7 billion settlement.

It pays to have a comprehensive, easily accessible record of each part at every stage of production to minimise disruptions. Product recalls, if not handled efficiently can result in considerable losses to and irreparable brand damage.

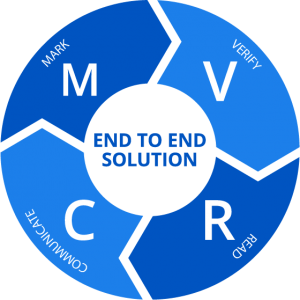

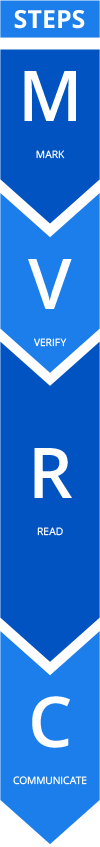

A complete solution to automotive traceability

| CHALLENGES |

|---|

| Encoding key information into a durable marking that can withstand the harsh conditions. |

| To ensure quality of the codes, prevent no-reads down the line and be able to track parts throughout their life cycle. |

| To be able to read codes accurately and be small enough to fit in to tight spaces To achieve reliable long distance communication within a high-mix production line. |

| Capturing and utilizing the date collected as much as possible without making the system overly complex. |

| SOLUTIONS |

|---|

MX-Z Laser Marker

High resolution marker offers high quality, permanent part identification for industrial traceability demands. |

LVS series Verifiers

Ultra-high-density inspection capabilities to grade even the smallest codes needed. |

MicroHAWK Barcode Readers

Small enough to fit into space-constrained assembly lines and rugged enough to withstand the harsh condition of automotive factory.

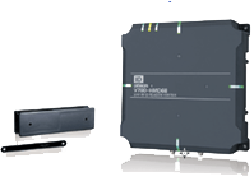

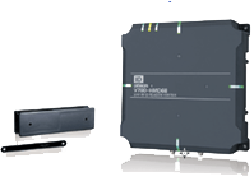

V780 UHF RFID System

Ultra-high frequency RFID system with all-in-one solutions that includes a reader, amplifier and an integrated antenna for traceability applications.

|

NX1 Automation Controller

Controller that integrates machine control with information utilization, quality management and safety over multiple networks without compromising control performance. |

Encoding key information into a durable marking that can withstand the harsh conditions.

High resolution marker offers high quality, permanent part identification for industrial traceability demands.

To ensure quality of the codes, prevent no-reads down the line and be able to track parts throughout their life cycle.

With ultra-high-density inspection capabilities to grade even the smallest codes needed.

To be able to read codes accurately and be small enough to fit in to tight spaces

To achive reliable long distance communication within a high-mix production line.

Small enough to fit into a space-constrained assembly lines and rugged enough to withstand the harsh condition of automotive factory.

Ultra-high frequency RFID system with all-in-one solutions that includes a reader, amplifier and an integrated antenna for traceability applications.

Encoding key information into a durable marking that can withstand the harsh conditions.

Controller that integrates machine control with information utilization, quality management and safety over multiple networks without compromising control performance.

Omron offers one-stop solutions to implement "cradle to grave" traceability for Automotive Industry.

productsExplore automotive traceability solutions that ensure quality,

consistency and compliance.