DO NOT REMOVE – CSS STYLESHEET

Increasing perception of threats to food integrity is driving the need for food safety measures. Without fine-tuned traceability protocols, consumers are exposed to defective products and companies are faced with the possibility of product recalls, which incurs an immediate cost and often result in a loss of future sales and significant long-term brand damage. In APAC region alone, consumers are holding manufacturers accountable in food safety scandals which cost over $8 billion USD every year.

Let us explore how Omron Traceability Solution can address these issues.

ISSUE 1 - Counterfeit Food

Counterfeiting has become a major problem in the food and beverage industry as the market becomes globalized. It jeopardizes health and safety - ultimately costing both manufacturers and consumers a great deal of money. Moreover, counterfeiting can severely damage trust and confidence in brands.

Due to the rising cases of fake food, consumers are demanding information on the ethicality of the source of raw materials going into food. This is most applicable to confection goods containing nuts or cocoa, as these raw materials are often sourced using child labor or other forms of labor in violation of international law.

SOLUTION - OMRON Traceability Solution through Serialization

One of the best ways to resolve these issues is by implementing a traceability system in F&B industry, which are in the best interest of both consumers and manufacturers.

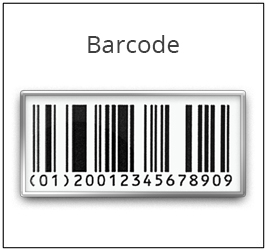

OMRON offers a robust traceability solution for inspecting, aggregating, managing and exchanging serialised data in the factory internal packaging process. By placing a serialized code on each product package, manufacturers can ensure the authenticity of products and provide all the necessary assurances to their consumers.

ISSUE 2 – Packaging & labelling Errors

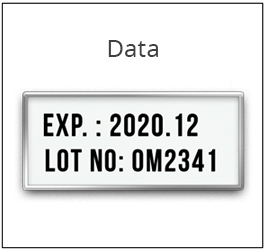

Did you know? Errors on labels and packaging are the most common cause of food and beverage recalls. Problems with product authenticity don’t always come from the outside. Mistakes in manufacturing can result with packages that inaccurate information.

Anyone with a peanut allergy knows, this is a potentially life-threatening issue. Food and beverage packaging must be extremely specific about what’s inside, and if there’s an information mismatch, the affected product needs to be recalled immediately.

According to IBM Consulting, 57% of customers will avoid purchasing brands that have been associated with a recall. This cost comes on top of the expenses that are directly associated with logistical issues of the recall.

SOLUTION – Eliminate human error in packaging and labelling process

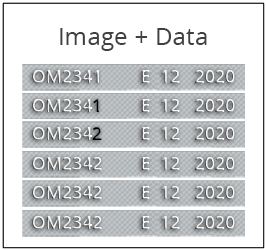

Label artwork and packaging for all products are now commonly similar, with only a small difference, if makes it hard to distinguish one design from another. This is where automation can help to eliminate the human error.

Omron puts ease of use at the core of its machine vision technology so that manufacturers do not need to rely on experts to get things up and running. In addition to high-performance smart cameras, Omron’s full vision systems the FH Series focuses on ease of use, enables high-speed, high-accuracy inspection and measurement functionality designed to meet or exceed the need for rapidly growing automation and higher performance requirements in industries like food and beverage packaging.

Since recalls can have a catastrophic impact on a company’s reputation as well as its profits, minimizing errors on labels and packaging is essential.

ISSUE 3 – Data Processing

By collecting and analyzing operational data, manufacturers can figure out which machines are under-performing and pinpoint precisely where bottlenecks are occurring in production. However, when traditional controllers are tasked with processing large amounts of traceability data, they are liable to slow down the production cycle time. This eventually leads to a longer production time and create an impact on overall production costs.

SOLUTION – OMRON High Speed Controller

Omron addresses this issue by developing controllers that can maintain high-speed control while handling all the information a traceability system provides. For example, the NX1 controller can be used for a packaging machine with the capability of handling 1,000 products per minute and can collect all traceability data in synchronization with the production cycle while performing motion control. This means that traceability doesn’t need to slow down other aspects of production while fulfilling the purpose of collecting important data.

VALUE – A Seamless Traceability Solution, Easy to Integrate and Easy to Use

Omron strives to make traceability as easy as possible, just as it strives to make its machine vision technology intuitive enough for the average operator to use. Our traceability solutions address various pain points that manufacturers face in the food and beverage packaging industry so that real-time, automated traceability is easy to achieve.

APPLICATIONS

Serialization on food packaging

Capturing Batch & Expiry Info

Readability of 1D Code

RELATED PRODUCTS

Omron Microhawk – Precision traceability & inspection solutions.

Omron NX1 – High-speed machine automation controller.

Omron FHV7 Series – Compact yet powerful solution for advanced defect detection.