Industry’s First Complete, Fully Integrated

Robotic Automation Solution

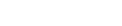

If you’re involved in manufacturing or packaging, you know that implementing and maintaining a robotic automated solution is no small task. OMRON offers the industry’s first complete and fully integrated robotic automation solution for sortation and placement - it’s simple, intuitive and hassle-free.

A Single Cohesive Solution To Automate Your Line Efficiency

Integrating technologies from different vendors can get complicated, time-consuming and expensive when something goes wrong or during product changeover. With OMRON single source solution, all components are designed to work together to maximise line productivity and efficiency.

Key Highlights For OMRON Sortation & Placement Solution

- Boost productivity with better system synchronization

- Increase line efficiency with fast changeovers

- Maximise throughput, with up to 8 robots and 8 vision cameras in place

- Easy implementation and hassle-free (one contact point for support)

FH Vision

With exceptionally efficient image handling characteristics, OMRON new vision system controller can support up to 8 high-resolution cameras, without compromising on performance or image capture speed.

This allows operators to handle even the most complex of inspection tasks and achieve operational efficiency.

- Accurate sorting with color recognition ability

- High speed, easy integration

- Can control up to 8 cameras

NJ Controller

OMRON NJ Controller is a scalable machine controller that can handles multiple functionalities. It controls all motion devices in the machine, including single axis, simple groups of axes and robot control, by providing independent or synchronized movements.

Capable of operating up to 8 robots within 2 msec, this system responds to the most demanding Pick & Place applications even at variable conveyor speed conditions. The latest control algorithms developed in the NJ reduce vibrations and ensure the smoothest TCP trajectories when handling the required products at higher throughput.

- Supports up to 8 high-resolution cameras

- Supports up to 8 parallel robots

- Provides advanced diagnostics with NA HMI

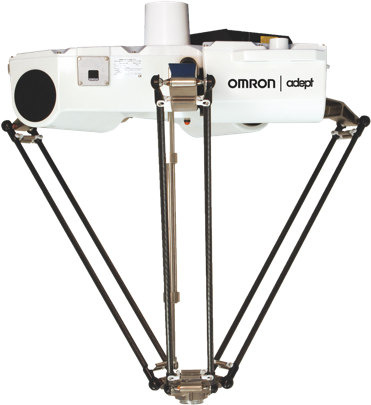

Parallel Robots

Building high performance Pick & Place machines becomes an easy job, thanks to the usability of the fully integrated Sysmac automation platform with integrated Vision and Robotics functionality.

Integrated with NJ Controller, operators can control up to 8 powerful parallel robots via a single controller. Operating at more than 200 cycle/min per robot, maximum throughput can be achieved in your Pick & Place applications, while ensuring full consistency in speed and accuracy.