Frequently asked questions and answers for Emergency Stop Switches - Industrial Automation

How can I replace the LED lamp for A22E Emergency Stop Switch with LED illumination?

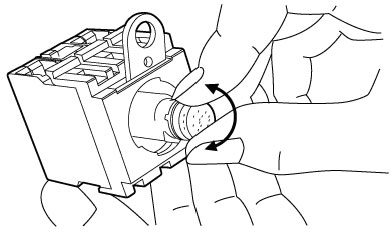

Remove the lock lever and separate the Operation Unit and the Socket Unit. Grip the LED lamp with your fingers, and then rotate the lamp while pressing it into the Socket Unit.

Follow steps 1 and 2 below.

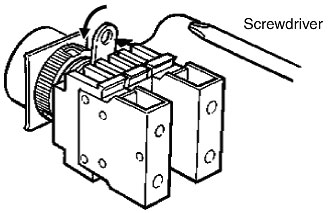

Move the lever in the direction indicated by the arrow in the following figure, and then pull the Operation Unit or the Socket Unit. The lever has a hole with an inside diameter of 6.5 mm, so the lever can be moved in the specified direction by inserting a screwdriver into the hole and then moving the screwdriver.

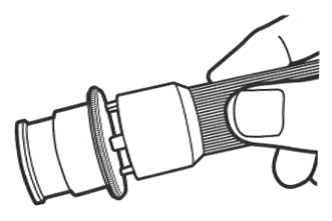

Using the Tightening Wrench (A22Z-3905), separate the cap from the Operation Unit. Use the Lamp Extractor (A22Z-3901) to replace the LED lamp.

Follow the steps 1 and 2 below.

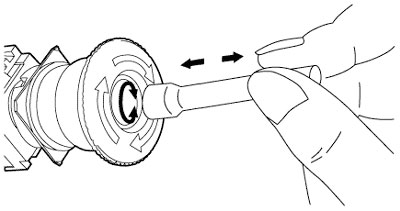

Insert the Lamp Extractor (A22Z-3901) into the lamp, and then rotate the Extractor while pressing in.

What are the restrictions when soldering A165E series Emergency Stop Switches?

There are the following restrictions.

What is the difference between a push button switch for an emergency stop and a general-purpose push button switch?

A general-purpose push button switch is used for controls, e.g., to start machine operation or to switch modes. An emergency stop push button switch is used as a safety measure to stop hazardous parts (loads).

An Emergency Stop Switch must be highly visible in color and shape, and must be easy to operate in emergency situations. The following requirements are specified in the European Standard EN 418 (International Standard: ISO13850).

In addition to the 4 points mentioned above, the emergency stop control circuit must have countermeasures for each category.

here is no difference between a general-purpose push button switch and an emergency push button switch regarding the function of the NO contact.

A general-purpose push button switch doesn't have a direct opening mechanism on the NC contact. If the contact welds, conduction will be maintained and the device cannot be stopped in a hazardous situation (load). If this occurs, the device may keep operating in the hazardous state. Therefore, use the NC contact of an emergency stop push button switch for safety applications.

Why can't a Programmable Controller or Programmable Terminal be used for the safety circuit?

The IEC 60204-1 (JIS B 9960-1) standard specifies that a safety circuit cannot be made using a programmable controller alone. This comes from the general requirement of the same standard that safety related functions must be constructed from proven circuit technology and parts. If the circuit relies on the operation of programmable electronic devices, this requirement may not be satisfied.

Can crimp terminals be used for wiring of A22E series Emergency Stop Switches?

Yes.

Please use crimp terminals with a diameter of 8 mm or less.

What is a push-pull?

It is a type of switch that is pushed in to begin operation and pulled out to release the lock.

Applicable models: Emergency Stop Switches

A22E-MP-[][]

A22E-LP-[][]

Does A165E/A22E Series Emergency Stop Switches have waterproof caps as accessories?

No.

The protection structure of both A165E-series and A22E-series meet the requirements of IP65.

How do I replace the LED for Lighted A165E Emergency Stop Switch?

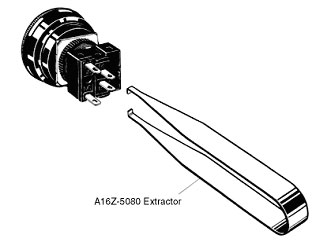

Replace the LED by separating the operation unit and the socket unit with A16Z-5080 Socket Unit lamp Extractor. Refer to the following steps 1 to 3 for the replacement procedure

Insert A16Z-5080 Extractor into the case guide slot shown in figure below and pull the socket unit straight out while pinching it with the Extractor.

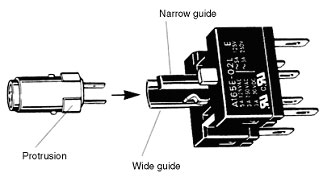

The following figure shows the mounting direction. Insert the LED so that the protrusions on the LED line up with the narrow guides on the socket unit.

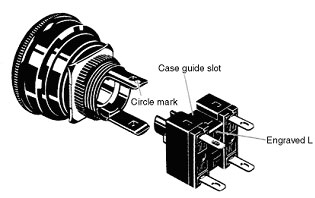

Mount the socket unit into the operation unit. There is a specific direction for assembling the operation unit and the socket unit. Assemble the two together with the circle mark on the operation unit aligned with the L engraved in the case guide slot and press until you hear a clicking sound. Also make sure there is no lifting or other problems

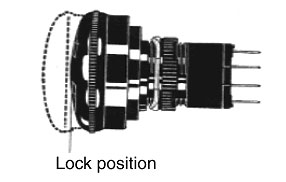

What is a safety lock mechanism?

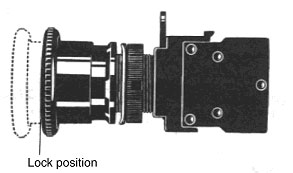

This switch can be intentionally used to stop equipment in an emergency. Even if an object or person touches the push button by mistake, the contact will not be released unless the push button reaches the lock position.

What is a push-lock key reset?

It is a type of switch that is pushed in to begin operation and unlocked with a special key.

Applicable models: Emergency Stop Switches

A22E-SK-[][]

A22E-MK-[]

What is a push-lock turn-reset?

It is a type of switch that is pushed in to begin operation and rotated to release the lock.

Applicable models: Emergency Stop Switches

A165E-series

A22E-S-[][]

A22E-M-[][]

A22E-L-[][]

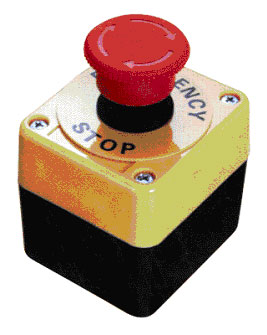

Is the color of the Emergency Stop Switch regulated?

The color is regulated by EN 418, ISO 13850, and JIS 9703. A push button switch that is used for emergency situations must be red, and the background must be yellow.

OMRON also provides emergency stop switches integrated with a control boxes. (A22E Series only.) The colors are as given above. A yellow control box is integrated with an emergency stop switch, a legend plate for EMERGENCY STOP, and a connector cable. This Switch complies with IP65 degree of protection.

Do the Lighted Models of A165E/A22E Series Emergency Stop Switches require external resistance for the LED?

An LED current-limiting resistor is built-in, so internal resistance is not required.

Why does an Emergency Stop Switch use a NC contact?

An NO contact cannot be used for a direct opening mechanism. A NC contact is always used for an Emergency Stop Switch.