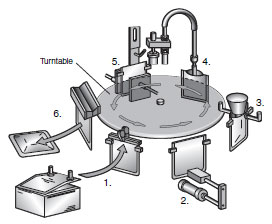

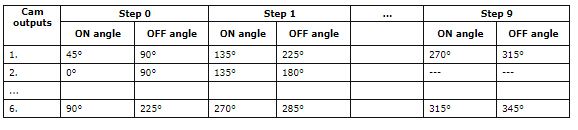

Cam Positioners detect angles of rotation by means of absolute encoders and give output signals according to the preset ON and OFF angles (Cam program).

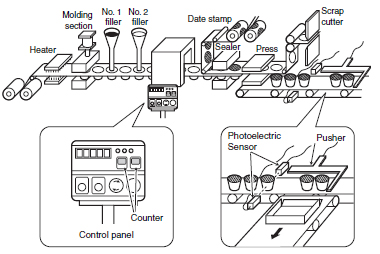

A Cam Positioner obtains angle data from an input device (e.g., an Encoder or Resolver) and uses preset ON/OFF angle settings to turn outputs ON and OFF. In food packing machines, for example, the Cam Positioner uses angle position data to control the timing of various mechanisms. The purpose of Cam Positioners is generally this type of timing control.

1. Control of the arm that supplies bags from the magazine

2. Control of the pump-driven cylinder

3. Control of filling a solid object with a specific amount of liquid

4. Control of the plunger and pump used to fill a body with a specific amount of liquid

5. Control of pouch sealing and air removal

6. Control of the metal seal pressing time and discharge arm

Unlike Encoders, Resolvers are simply structured and have no electronic components so their performance is virtually unaffected by dust or vibration. This makes them highly reliable and environmentally resistant. Because they are brushless as well, they are maintenance free and their service life depends solely on the ball bearings.

Resolvers boast excellent environmental resistance, particularly against oil, dust, temperature, and shock. They also have an ambient operating temperature range of -10 to 80°C.

Resolvers can detect absolute angles and only one Resolver is needed for high-precision at 360 and 720 resolutions.

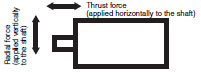

With a radial and thrust shaft-load tolerance of 196 N, Resolvers outclass all other detectors, such as Encoders.

Resolver cables can be extended up to 100 m to enable remote operation and control from a location well away from the Resolver.

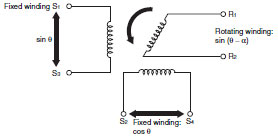

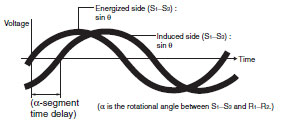

As shown in the following diagram, sin ? and cos ? voltage is applied to the two sets of fixed windings, S1-S3 and S2-S4, respectively, that are mechanically 90° out of phase. Observing the sin (? - a) voltage induced in the rotating winding R1-R2 makes the Resolver a kind of rotating transformer that detects angles.

If the fixed winding is locked in position completely in phase with fixed winding S1-S3 (energized by sin ? voltage) for example, then sin ? voltage will be induced in R1-R2. When the rotating winding starts rotating, sin (? - a) voltage will be induced in R1-R2 because of the cos ? voltage of the S2-S4 winding that is 90° out of phase with the S1-S3 winding. (See the figure below.)

Thrust and radial forces represent the maximum vertical and horizontal forces applied to a shaft. The magnitude of these forces is proportionally related to the service life of the product (i.e., the mechanical service life of the bearings).

When a Resolver is linked to a mechanical system, the Resolver origin can be easily adjusted to match the machine origin if they are not the same. The process of aligning the two origins is called origin compensation.

All the values are approximate values and should therefore only be used as a guide.