Photoelectric Sensors detect photo-optical workpieces. OMRON provides many varieties of Sensor, including diffuse-reflective, through-beam, retro-reflective, and distance-settable Sensors, as well as Sensors with either built-in or separate amplifiers and Fiber Units.

Photoelectric Sensors detect objects, changes in surface conditions, and other items through a variety of optical properties.

A Photoelectric Sensor consists primarily of an Emitter for emitting light and a Receiver for receiving light. When emitted light is interrupted or reflected by the sensing object, it changes the amount of light that arrives at the Receiver. The Receiver detects this change and converts it to an electrical output. The light source for the majority of Photoelectric Sensors is infrared or visible light (generally red, or green/blue for identifying colors).

Photoelectric Sensors are classified as shown in the figure below. (See Classification.)

A Through-beam Sensor, for example, can detect objects more than 10 m away. This is impossible with magnetic, ultrasonic, or other sensing methods.

These Sensors operate on the principle that an object interrupts or reflects light, so they are not limited like Proximity Sensors to detecting metal objects. This means they can be used to detect virtually any object, including glass, plastic, wood, and liquid.

The response time is extremely fast because light travels at high speed and the Sensor performs no mechanical operations because all circuits are comprised of electronic components.

The incredibly high resolution achieved with these Sensors derives from advanced design technologies that yielded a very small spot beam and a unique optical system for receiving light.

These developments enable detecting very small objects, as well as precise position detection.

There is little chance of damaging sensing objects or Sensors because objects can be detected without physical contact.

This ensures years of Sensor service.

The rate at which an object reflects or absorbs light depends on both the wavelength of the emitted light and the color of the object. This property can be used to detect colors.

Positioning the beam on an object is simple with models that emit visible light because the beam is visible.

When light travels through air or water, it always travels in a straight line. The slit on the outside of a Through-beam Sensor that is used to detect small objects is an example of how this principle is applied to practical use.

Refraction is the phenomenon of light being deflected as it passes obliquely through the boundary between two media with different refractive indices.

A flat surface, such as glass or a mirror, reflects light at an angle equal to the incident angle of the light. This kind of reflection is called regular reflection. A corner cube takes advantage of this principle by arranging three flat surfaces perpendicular to each other. Light emitted toward a corner cube repeatedly propagates regular reflections and the reflected light ultimately moves straight back toward the emitted light. This is referred to as retro-reflection.

Most retro-reflectors are comprised of corner cubes that measure several square millimeters and are arranged in a precise configuration.

Matte surfaces, such as white paper, reflect light in all directions. This scattering of light is called diffuse reflection. This principle is the sensing method used by Diffuse-reflective Sensors.

Light can be represented as a wave that oscillates horizontally and vertically. Photoelectric Sensors almost always use LEDs as the light source. The light emitted from LEDs oscillates in the vertical and horizontal directions and is referred to as unpolarized light. There are optical filters that constrain the oscillations of unpolarized light to just one direction. These are known as polarizing filters. Light from an LED that passes through a polarizing filter oscillates in only one direction and is referred to as polarized light (or more precisely, linear polarized light). Polarized light oscillating in one direction (say the vertical direction) cannot pass through a polarizing filter that constrains oscillations to a perpendicular direction (e.g., the horizontal direction). The MSR function on Retro-reflective Sensors and the Mutual Interference Protection Filter accessory for Through-beam Sensors operate on this principle.

The majority of Photoelectric Sensors use pulse modulated light that basically emits light repeatedly at fixed intervals. They can sense objects located some distance away because the effects of external light interference are easily removed with this system. In models equipped with mutual interference protection, the emission cycle is varied within a specified range to handle coherent light and external light interference.

Non-modulated light refers to an uninterrupted beam of light at a specific intensity that is used with certain types of Sensors, such as Mark Sensors. Although these Sensors have fast response times, their drawbacks include short sensing distances and susceptibility to external light interference.

With no electrical components in the sensing section (fiber), the Optical Fiber Sensor is highly resistant to noise and other environmental influences.

Optical fiber is comprised of a central core with a high refractive index surrounded by cladding with a low refractive index. When light enters the core, repetitive total internal reflection at the boundary of the less refractive cladding guides the light down the optical fiber. The angle of the light traveling through the optical fiber increases to about 60° by the time the light exits the fiber and strikes a sensing object.

Distance-settable Sensors generally operate on the principle of triangulation. This principle is illustrated in the following diagram.

Light from the Emitter strikes the sensing object and reflects diffused light. The Receiver lens concentrates the reflected light on the position detector (a semiconductor that outputs a signal according to where the light strikes it). When the sensing object is located at A near the optical system, then the light is concentrated at point a on the position detector. When the sensing object is located at B away from the optical system, then the light is concentrated at point b on the position detector.

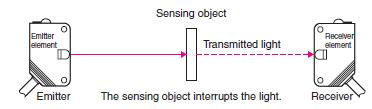

The Emitter and Receiver are installed opposite each other to enable the light from the Emitter to enter the Receiver. When a sensing object passing between the Emitter and Receiver interrupts the emitted light, it reduces the amount of light that enters the Receiver. This reduction in light intensity is used to detect an object.

The sensing method is identical to that of Through-beam Sensors and some models called Slot Sensors are configured with an integrated Emitter and Receiver.

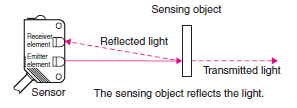

The Emitter and Receiver are installed in the same housing and light normally does not return to the Receiver. When light from the Emitter strikes the sensing object, the object reflects the light and it enters the Receiver where the intensity of light is increased. This increase in light intensity is used to detect the object.

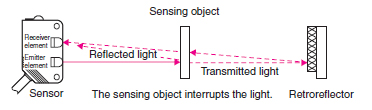

The Emitter and Receiver are installed in the same housing and light from the Emitter is normally reflected back to the Receiver by a Reflector installed on the opposite side. When the sensing object interrupts the light, it reduces the amount of light received. This reduction in light intensity is used to detect the object.

The Receiver in the Sensor is either a 2-part photodiode or a position detector. The light reflected from the sensing object is concentrated on the Receiver. Sensing is based on the principle of triangulation, which states that where the beam is concentrated depends on the distance to the sensing object.

The following figure shows a detection system that uses a 2-part photodiode. The end of the photodiode nearest the case is called the N (near) end and the other end is called the F (far) end. When a sensing object reaches the preset position, the reflected light is concentrated midway between the N end and the F end and the photodiodes at both ends receive an equal amount of light. If the sensing object is closer to the Sensor, then the reflected light is concentrated at the N end. Conversely, the reflected light is concentrated at the F end when the sensing object is located farther than the preset distance. The Sensor calculates the difference between the light intensity at the N end and F end to determine the position of the sensing object.

When using the E3Z-LS61, E3Z-LS66, E3Z-LS81, or E3Z-LS86, select the BGS or FGS function to detect objects on a conveyor belt.

The BGS function prevents any background object (i.e., the conveyor) beyond the set distance from being detected.

The FGS function prevents objects closer than the set distance or objects that reflect less than a specified amount of light to the Receiver from being detected. Objects that reflect less than a specified amount of light are as follows:

Reflected light may return to the Receiver momentarily for item (3) due to sensing object movement. In that case, an OFF delay timer or some other means may need to be employed to prevent chattering.

In the same way as for Diffuse-reflective Sensors, Limited-reflective Sensors receive light reflected from the sensing object to detect it. The Emitter and Receiver are installed to receive only regular-reflection light, so only objects that are a specific distance (area where light emission and reception overlap) from the Sensor can be detected. In the figure on the right, the sensing object at (A) can be detected while the object at (B) cannot.

1. Size and shape (vertical x horizontal x height)

2. Transparency (opaque, semi-transparent, transparent)

3. Velocity V (m/s or units/min.)

1. Sensing distance (L)

2. Restrictions on size and shape

a) Sensor

b) Retro-reflector (for Retro-reflective Sensors)

3. Need for side-by-side mounting

a) No. of units

b) Mounting pitch

c) Need for staggered mounting

1. Ambient temperature

2. Presence of splashing water, oil, or chemicals

3. Others

1. Size and shape (vertical x horizontal x height)

2. Color

3. Material (steel, SUS, wood, paper, etc.)

4. Surface conditions (textured or glossy)

5. Velocity V (m/s or units/min.)

1. Sensing distance (distance to the workpiece) (L)

2. Restrictions on size and shape

3. Need for side-by-side mounting

a) No. of units

b) Mounting pitch

4. Mounting restrictions (angling, etc.)

1. Color

2. Material (steel, SUS, wood, paper, etc.)

3. Surface conditions (textured, glossy, etc.)

1. Ambient temperature

2. Presence of splashing water, oil, or chemicals

3. Others

Photoelectric Sensors are generally comprised of an Emitter, Receiver, Amplifier, Controller, and Power Supply. They are classified as shown below according to how the components are configured.

Through-beam Sensors have a separate Emitter and Receiver while Reflective Sensors have an integrated Emitter and Receiver.

The Amplifier and Controller are housed in a single Amplifier Unit.

Everything except the power supply is integrated in these Sensors. (Through-beam Sensors are divided into the Emitter comprised solely of the Emitter and the Receiver comprised of the Receiver, Amplifier, and Controller.) The power supply is a standalone unit.

The Power Supply, Emitter, and Receiver are all installed in the same housing with these Sensors.

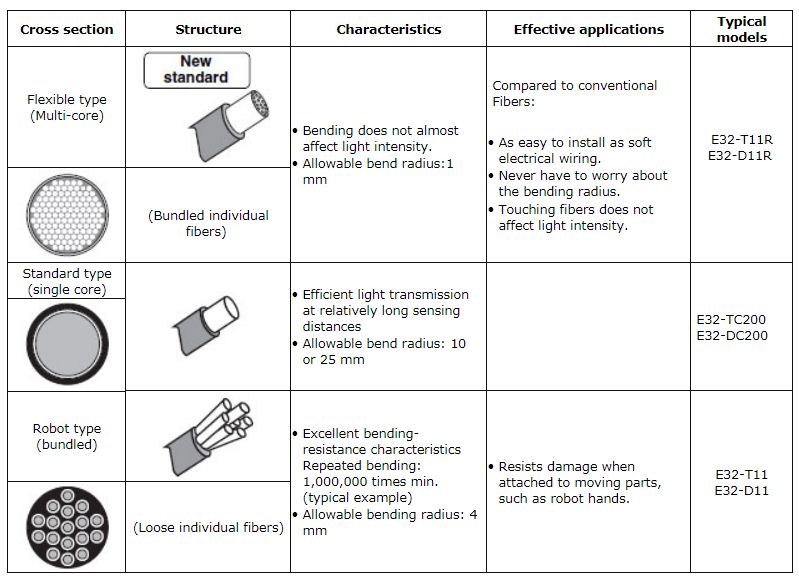

The Emitter and Receiver are connected by optical fiber. These Sensors are comprised of a Fiber Unit and an Amplifier Unit, but the OMRON product line does not include an Amplifier Unit with a built-in power supply.

Note: These values are for the standard sensing object. The operating area and sensing distance will change for a different object.

Note: These values are for the standard sensing object. The operating area and sensing distance will change for a different object.

The width and the operating range of E3X-DA-S+E32-DC200 (example) sensing object

The surface color and the sensing distance of E3X-DA-S+E32-DC200 (example) sensing object

The surface color and the operating range of E3X-DA-S+E32-DC200 (example) sensing object