These Optical Sensors provide a compact, low-cost method to detect workpieces. Many models are available, including Slot-type Sensors (through-beam) for non-modulated or modulated light, Reflective Sensors, and Sensors with separate emitters and receivers.

A Photomicrosensor is a small photoelectric sensor with an amplifier built into it that is used primarily as a component for building into equipment.

Like any ordinary photoelectric sensor with a built-in amplifier, it is used, for example, in applications to detect passing objects or in positioning applications. The sensing object is most often a piece of metal called a "dog". When the dog enters the sensing area, it is optically detected by the Photomicrosensor, which outputs a signal.

Photomicrosensors have the following advantages over ordinary photoelectric sensors with built-in amplifiers:

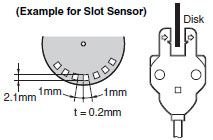

The EE-SX67 Series, for example, has models with eight different slot configurations, allowing the customer to choose the best configuration for the installation position.

Ratings and performances are limited to those required for building into equipment, and the required IP degree of protection is easier to achieve, making prices very reasonable.

The standard sensing distances (slot width) are specifically intended to be used for building into equipment. Slot-type Sensors, for example, have a 3.6 mm or 5 mm sensing distance. Diffuse-reflective and Limited Reflective Sensors have a sensing distance of less than 5 mm, and retro-reflective and Through-beam Sensors, less than 1 m.

The indicator on many Photomicrosensors lights when light is incident. Some Photomicrosensors have specific models on which the indicator lights when light is interrupted. When lighting the indicator for position adjustment applications of Slot-type Sensors, for example, it may be more convenient to use a model that lights the indicator when light is interrupted. When using the indicator to check the power supply status, on the other hand, it may be convenient to use a model that lights the indicator when light is incident.

A waterproof structure is not required because it is assumed the Photomicrosensors will be built into other equipment, and the output current rating can be kept low. Also, most models can operate on a 5-VDC power supply.

When light travels through air or water, it always travels in a straight line. The slit on the outside of a Through-beam Sensor that is used to detect small objects is an example of how this principle is applied to practical use.

Refraction is the phenomenon of light being deflected as it passes obliquely through the boundary between two media with different refractive indices.

A flat surface, such as glass or a mirror, reflects light at an angle equal to the incident angle of the light. This kind of reflection is called regular reflection. Retro-reflectors (also called a corner cube) take advantage of this principle by arranging three flat surfaces perpendicular to each other. "Retro" means "to return toward the source." The light reflected off the reflectors travels back towards the emitter, thus the term retro-reflective".

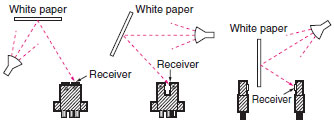

Matte surfaces, such as white paper, reflect light in all directions. This scattering of light is called diffuse reflection. This principle is the sensing method used by Diffuse-reflective Sensors.

Non-modulated light facilitates high-speed response by continuously radiating a constant amount of light. There is the drawback, however, of susceptibility to external light interference.

Modulated light is not affected by sunlight, light from incandescent bulbs, and other external light interference. An LED emitter is pulse-lighted, and the received signal is processed to remove the DC component.

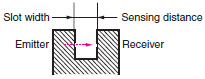

Slot Sensors are suitable for applications using a thin sensing object, or "dog," that require a highly precise sensing position. Setup is easy because no optical axis adjustment is needed. There are many product variations. The necessary configuration, connection method, and other items can be selected from a wide array of models.

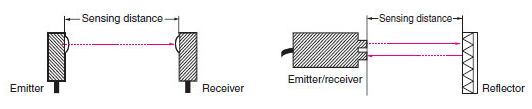

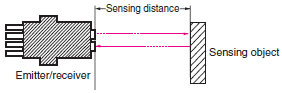

Through-beam Sensors are suitable for applications that require relatively long sensing distances.

Retroreflective Sensors are suitable for applications that require relatively long sensing distances. They have the advantage of requiring less work for wiring and optical axis adjustment when compared to Through-beam Sensors.

Diffuse-reflective Sensors are suitable for applications where the sensing object is thick and won't fit into the slot of a Slot Sensor.

Limited-reflective Sensors are basically the same as Diffuse-reflective Sensors, but they are suitable when background objects are present. (With Diffuse-reflective Sensors, the presence of a background object with a higher reflectivity than the sensing object (e.g., metals with mirror finishing) may cause sensing instability.)

Sample Characteristics for the EE-SX770

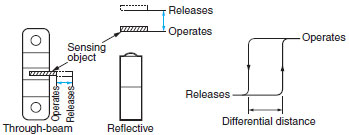

Indicates whether or not the Sensor responds with respect to sensing object edge position.

Sample Characteristics for the EE-SX770

Indicates the discrepancy in the edge position of the sensing object when the Sensor responds. It serves as a guide for the positioning accuracy of the sensing object.

Sample Characteristics for the EE-SPW311/411

Sample Characteristics for the EE-SPW311/411

Sample Characteristics for the EE-SPY301 and EE-SPY401

Note: These values apply to the standard sensing object. If the sensing object changes, the operating range and sensing distances also change.

Method used to detect light steadily emitted by the emitter element.

The slot width, i.e., the distance between the opposing faces of the emitter and receiver, is the sensing distance.

The minimum distance that can be set considering factors such as the variation between products and fluctuations in temperature.

Note: The actual value under standard conditions for each method is longer than the rated sensing distance.

The minimum distance that can be set for a standard sensing object (white paper) considering factors such as the variation between products and fluctuations in temperature.

Note: The actual value under standard conditions for each method is longer than the rated sensing distance.

The difference in distance between the operating point and releasing point.

The frequency at which an object satisfying specified conditions (size, transparency rate, reflection factor, sensing distance, and power supply voltage) can be repeatedly detected.

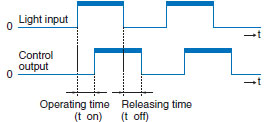

The delay from the light input turning ON/OFF until the control output operation or release operation. The following equation generally applies. Operating time (Ton) ≈ Releasing time (Toff)

The level of illumination on the sensing surface that enables stable operation of the Sensor.