Safety light curtains use blocked light to detect workers in hazardous machine areas and to stop machines before workers are injured. Unlike ordinary sensors, safety area sensors use a combination of hardware and software to check constantly for internal faults to ensure safe operation.

Safety light curtains use blocked light to detect workers in hazardous machine areas and to stop machines before workers are injured. Unlike ordinary sensors, safety area sensors use a combination of hardware and software to check constantly for internal faults to ensure safe operation.

The safety standards for safety area sensors are the same requirements stipulated for safety in the Machinery Directive, and European standards like IEC61496 ensure compliance with those requirements. IEC61496-1 stipulates exactly how type 4 ESPE will ensure safety for an accumulation of up to three faults. In the F3SJ, F3SN-A, F3SH-A, F3SL, F3SS and MS4800 safety was designed in by using dual CPUs that check each other as well as by using redundant signal processing and output circuits. FMEA * analysis was also used to demonstrate safe operation and thus ensure complete safety.

The F3SJ, F3SN-A, F3SH-A, F3SL and MS4800 Safety Light Curtains and F3SS Single-beam Safety Sensor can be used even with the most hazardous machines. (EC Machinery Directive Type 4)

These products can be used for all applications in categories B, 1, 2, 3, and 4 (ISO 13849-1) for safety-related parts produced for machine hazards. The F3SN-B and E3FS/E3ZS Single-beam Safety Sensors *, which are Type 2 Safety Area Sensors, can be used for applications in categories B, 1, and 2.

When safety area sensors are to be used with press equipment in Japan, they must pass the “model test” stipulated in Article 44, Item 2, of the Occupational Health and Safety Law. The F3SJ, F3SN, F3SH, F3SL and MS4800 have not been subjected to this model test, so they cannot be used in the applications described in Article 42 of the Occupational Health and Safety Law as “Safety devices for presses or shearing machines.”

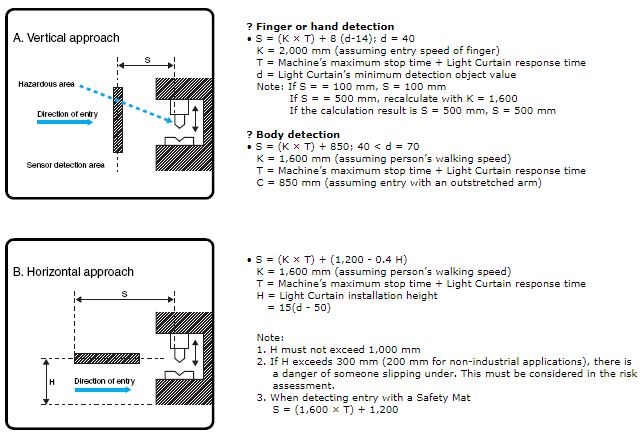

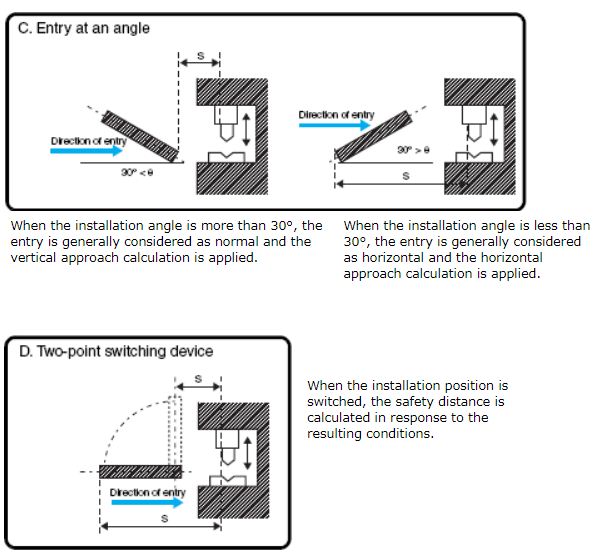

When installing a presence-sensing device, such as a Safety Light Curtain, the minimal distance that is required to stop the machine before a person who enters the detection zone will reach the machine is stipulated by EN999 and other standards.

Safety distance (S) = Person’s approach speed × response time + additional distance due to the sensor’s detection capability

The muting function temporarily stops the detection function of the Safety Light Curtain and automatically keeps it ON regardless of whether the light is incident or interrupted.

The muting function can be added to the Safety Light Curtain by connecting the F3SP-U2P Muting controller or by connecting the Safety Light Curtain with accessories (F3SJ + Muting Cap).

Conventionally when objects such as AGVs or transport pallets passed through the detection area, the work process was stopped by the light interruption of the Safety Light Curtain each time they passed. With the addition of the muting function, the safety output can be turned OFF only when a person enters the area, while automatically maintaining the safety output when a workpiece passes through. This makes it possible for work to continue without stopping the production line.

However, when muted, the safety detection function is deactivated, which means that it cannot output an OFF signal to the hazard source when a person enters the detection area.

The following items are necessary to add the muting function.

(Example)

F3SN-A Safety Light Curtain: 1 set

F3SP-U2P Muting Controller: 1

E3Z-R81 Muting Sensors: 2 sets

Muting Lamp (OMRON recommended product): 1

Note: The F3SP-U2P Muting Controller distinguishes the difference between a workpiece and a person passing through by the difference in the detection timing of Muting Sensors A and B. Adjust the installation locations and detection directions of Muting Sensors A and B so that the light will not be interrupted in both when a person passes through.

Workpieces and persons are distinguished by multiple Muting Sensors. Because a dangerous situation may occur if the installation positions and other factors are not correct for the Muting Sensors, have a person with sufficient knowledge and experience perform a risk assessment when deciding the selection, installation locations, detection directions, and other factors for the Muting Sensors.

For more details, refer to the operation manual for the F3SP-U2P Muting Controller.

It is necessary to alert people in the vicinity when muting is being used. A Muting Lamp must be installed for this purpose. Also, the F3SP-U2P is equipped with an override function that forcibly applies muting. The safety output is explicitly disabled by this function, so ample safety considerations must be made in it use.

Example of Improper Use

Example of Proper Use

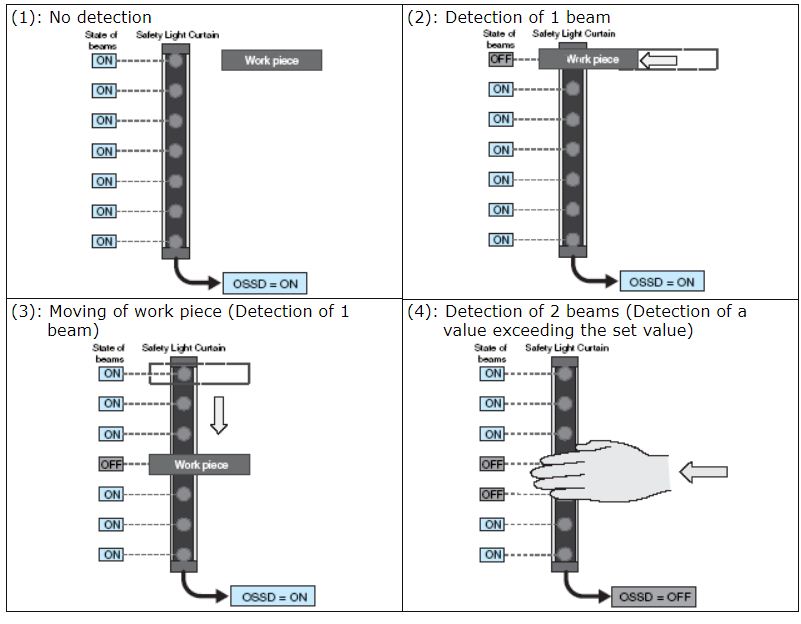

Some applications have problems in mounting the light curtain. Therefore it is helpful to take out zones from the protection field. With the blanking function it is possible to specify beams that will not be interrupted by the light curtain. This is called fixed blanking. The remaining field or zone has to be protected by mechanical guards.

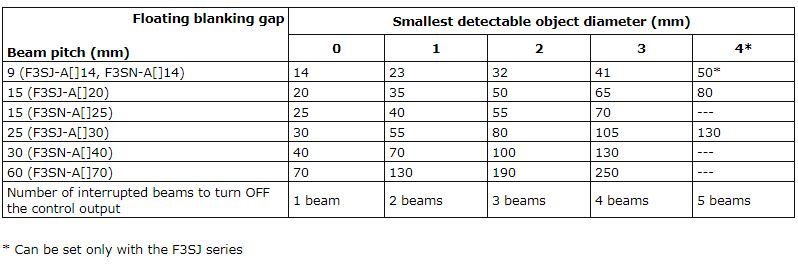

The floating blanking function allows the output to remain ON when beams of the sensor are interrupted anywhere in the protection field. In contrast with fixed blanking function, which invalidates the fixed detection area, the floating blanking function ignores objects smaller than a specified radius. This reduces the optical resolution.

When it is not possible to provide the entire take-up winder with a safety cover or other device.

For calculating the safety distance this reduced resolution has to be taken into account. (See table below.)