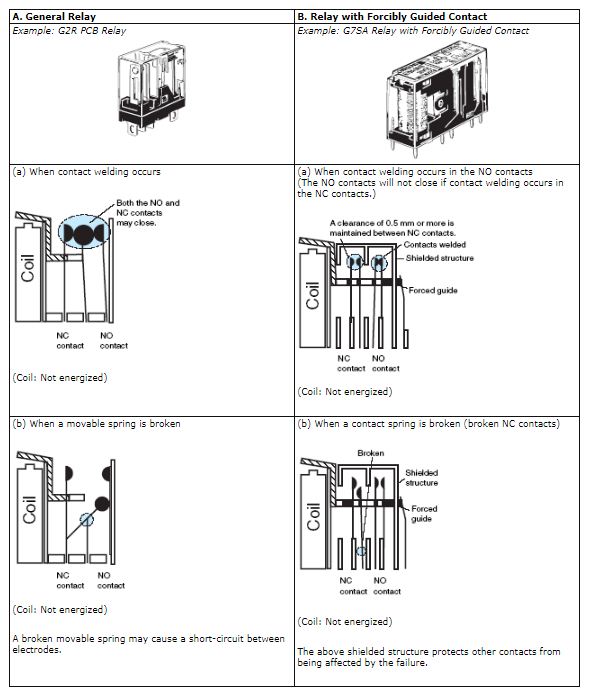

Unlike other relays, safety relays ensure the safety function even if contacts are welded together because they have forcibly guided (linked) contacts (EN 50205).

Note: Welding cannot be pulled apart.

If at least one normally open contact is welded, when the coil is de-energized, all normally closed contacts maintain a gap of at least 0.5 mm. Even if a normally closed contact is welded, all normally open contacts maintain a gap of at least 0.5 mm in the coil energized mode (in accordance with EN 50205).

Relays that use forcibly guided contacts for all of the contacts are called Class A and indicated by the mark.