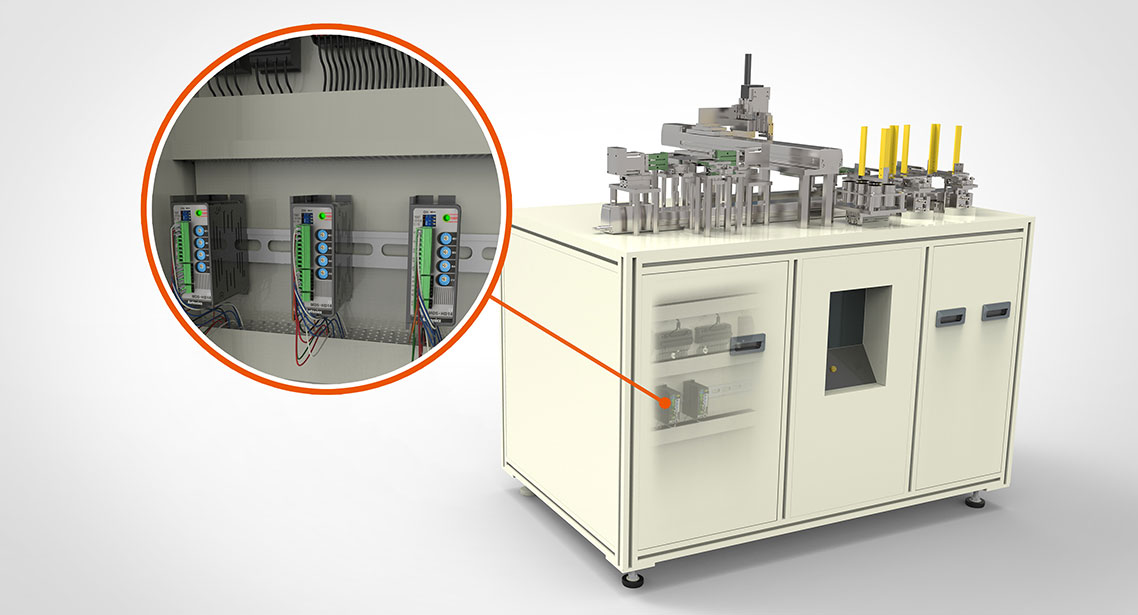

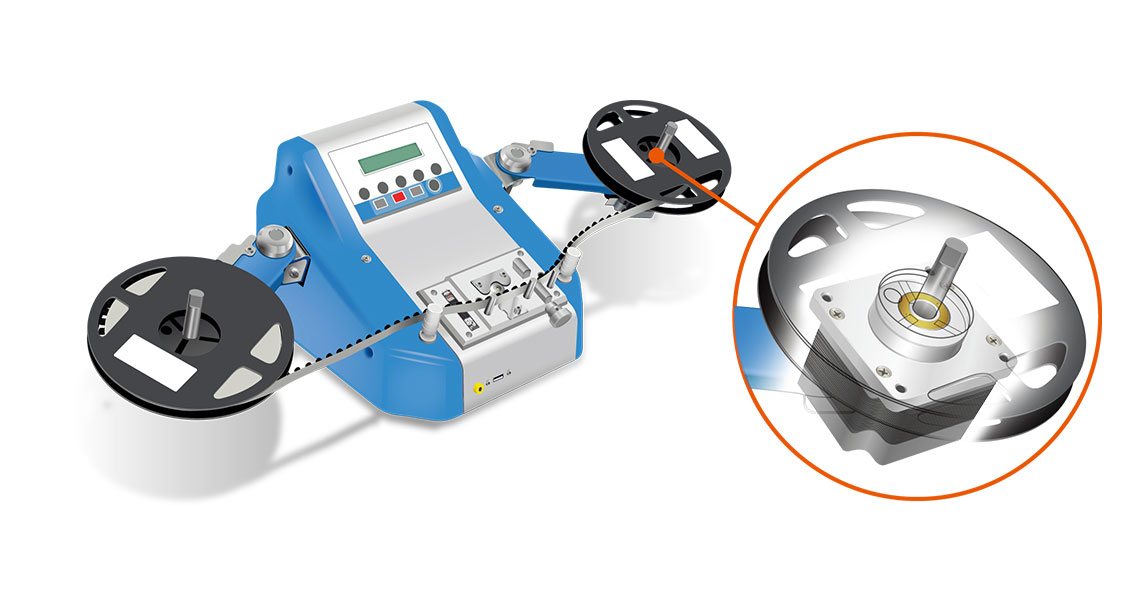

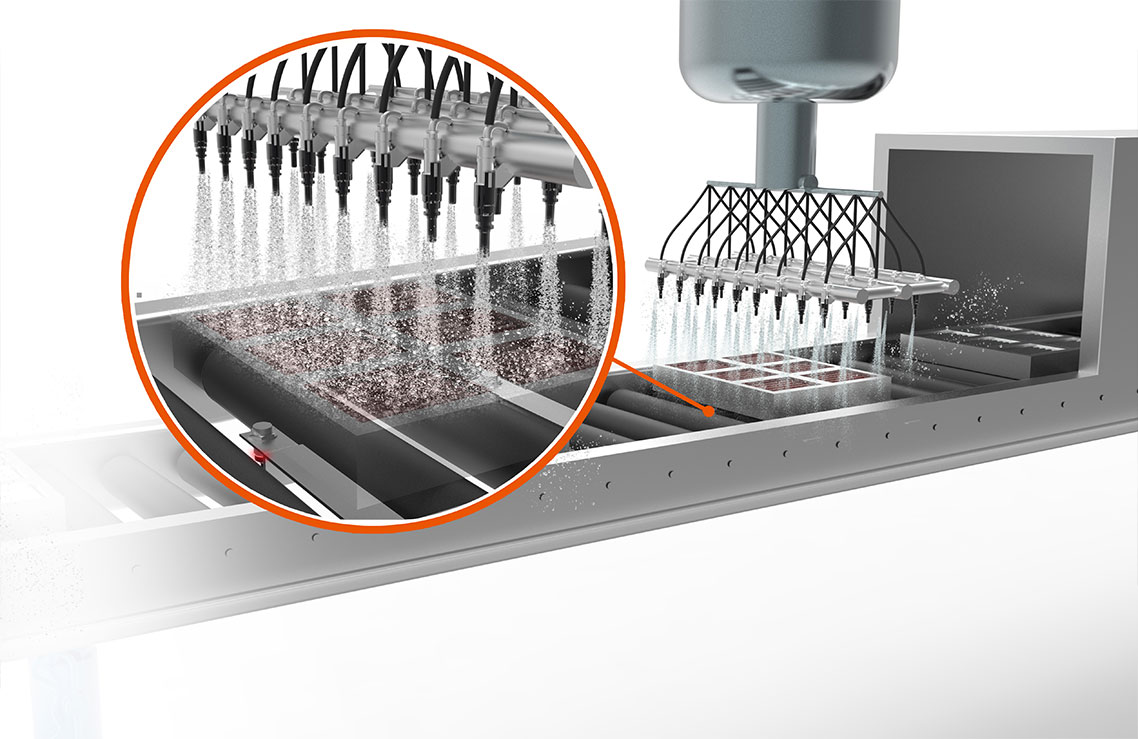

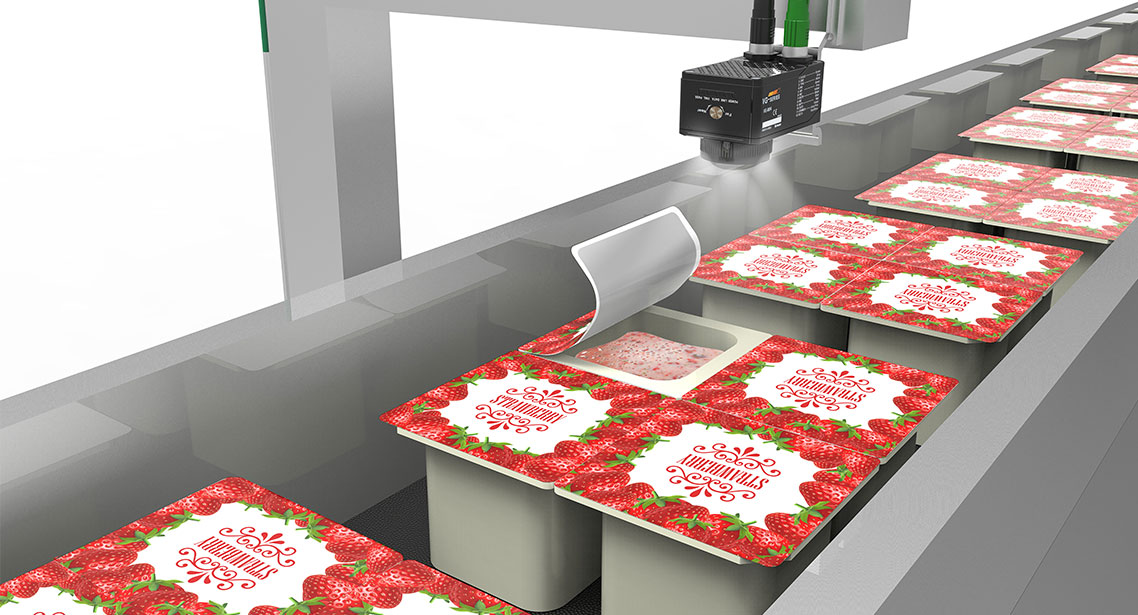

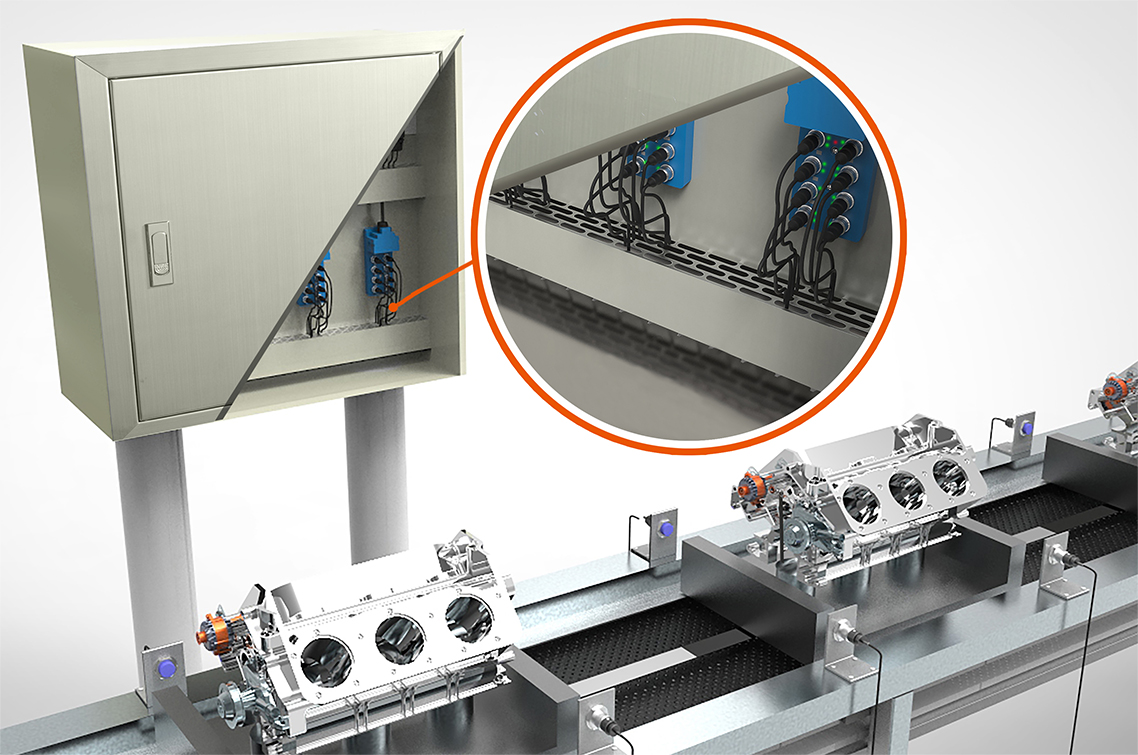

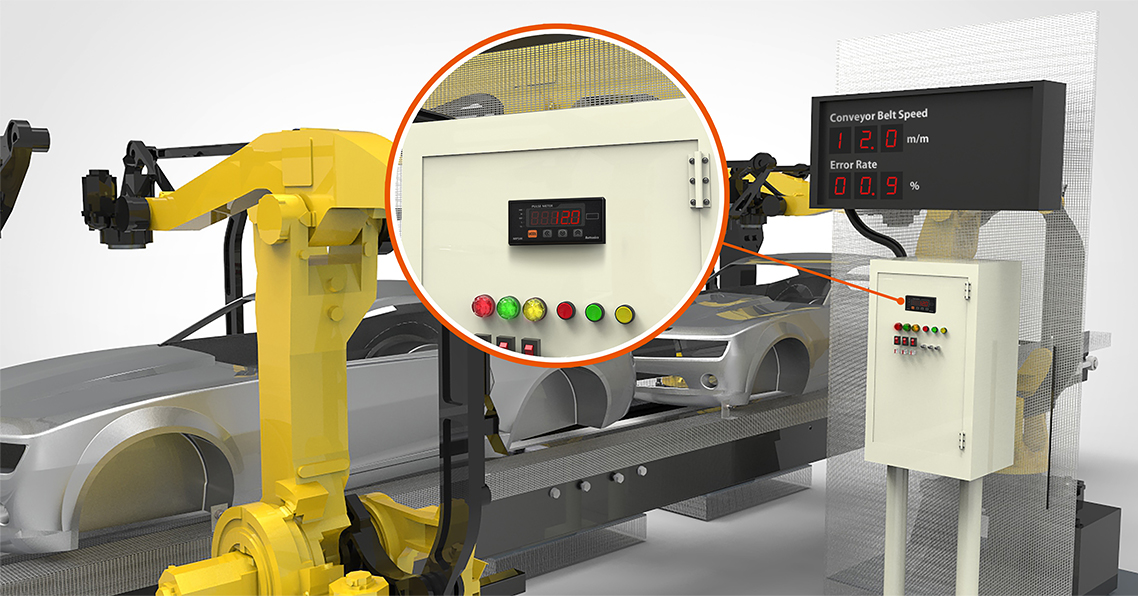

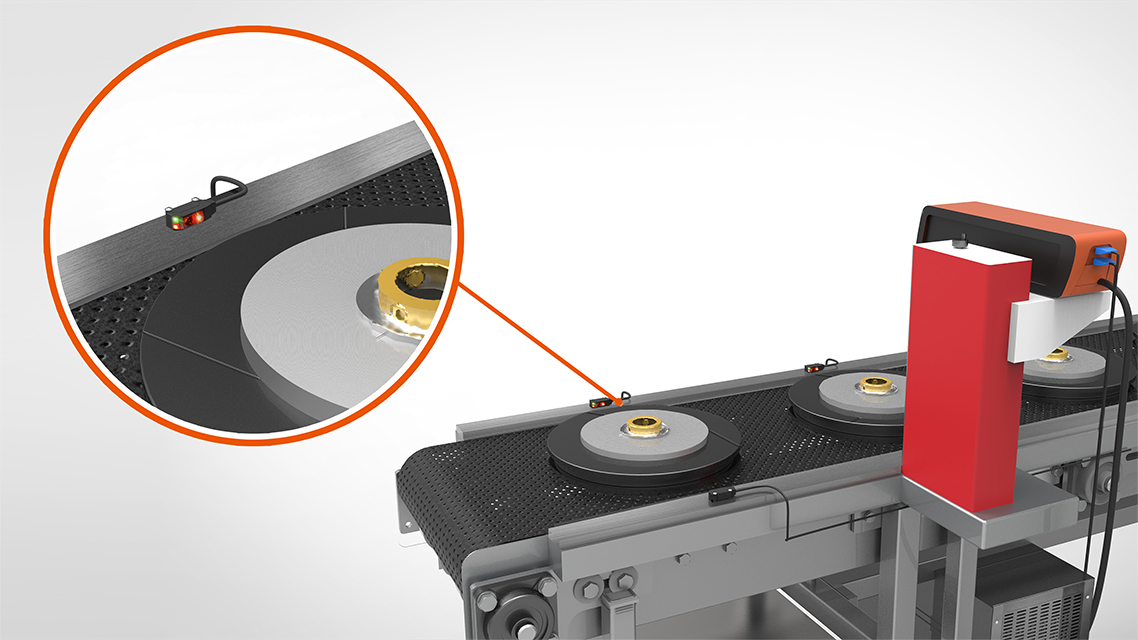

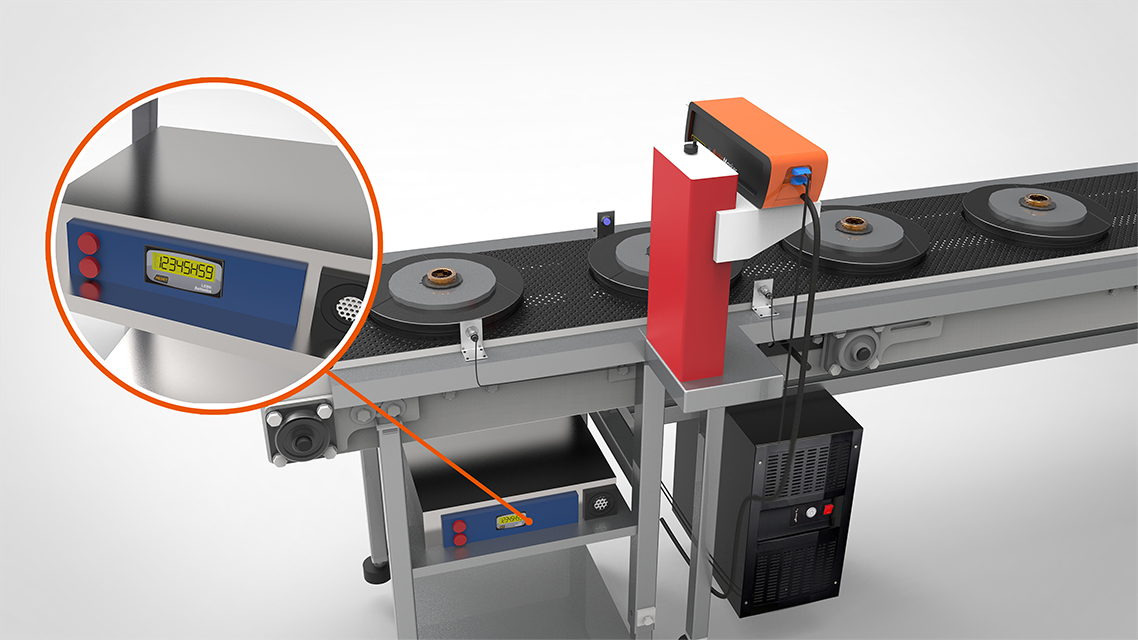

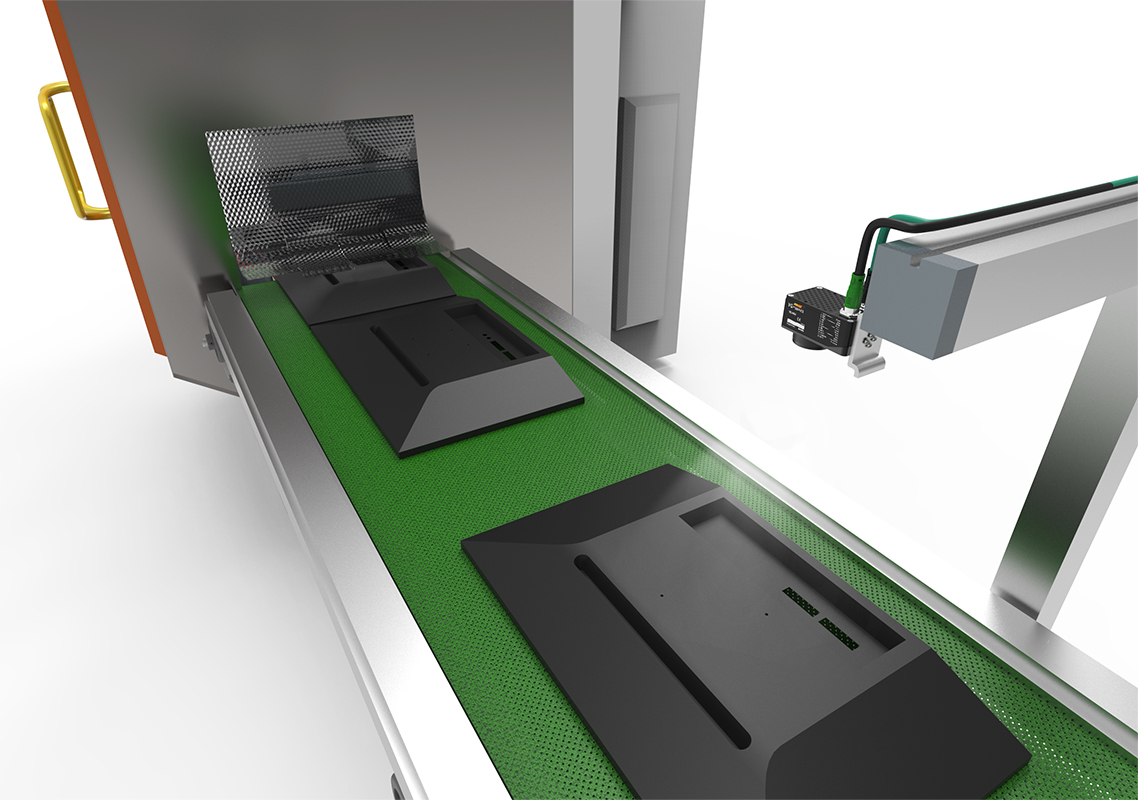

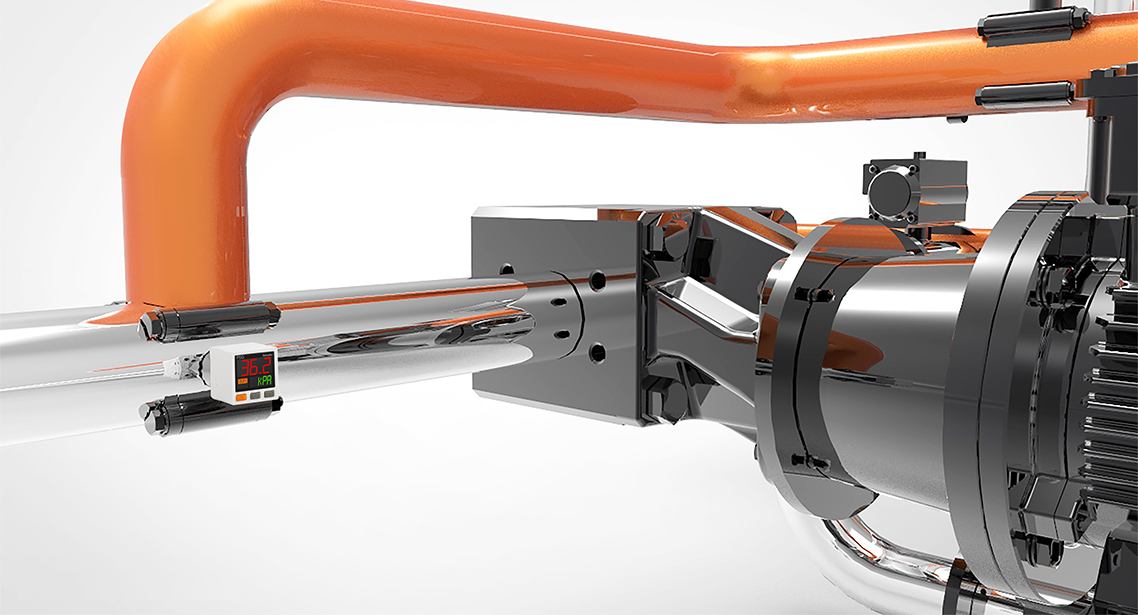

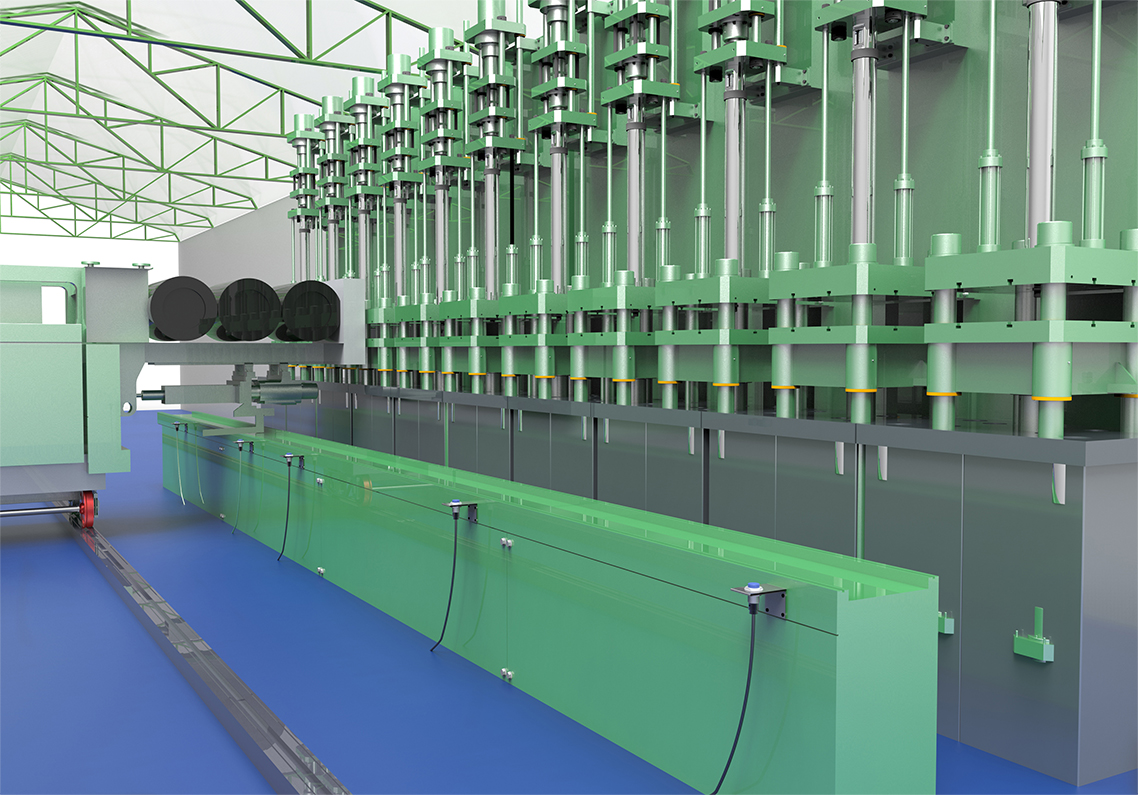

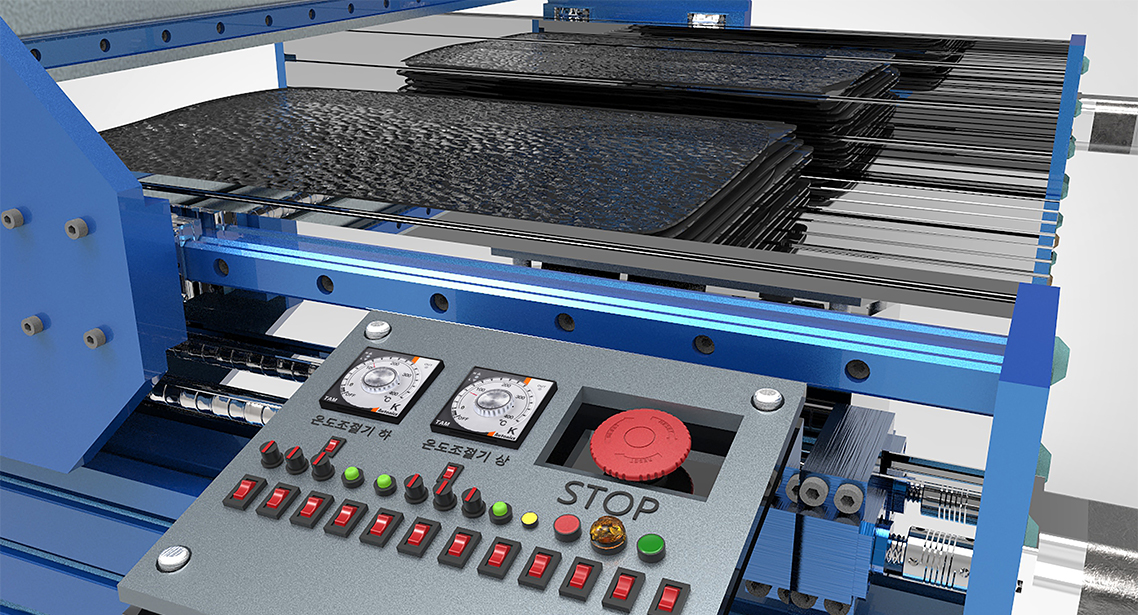

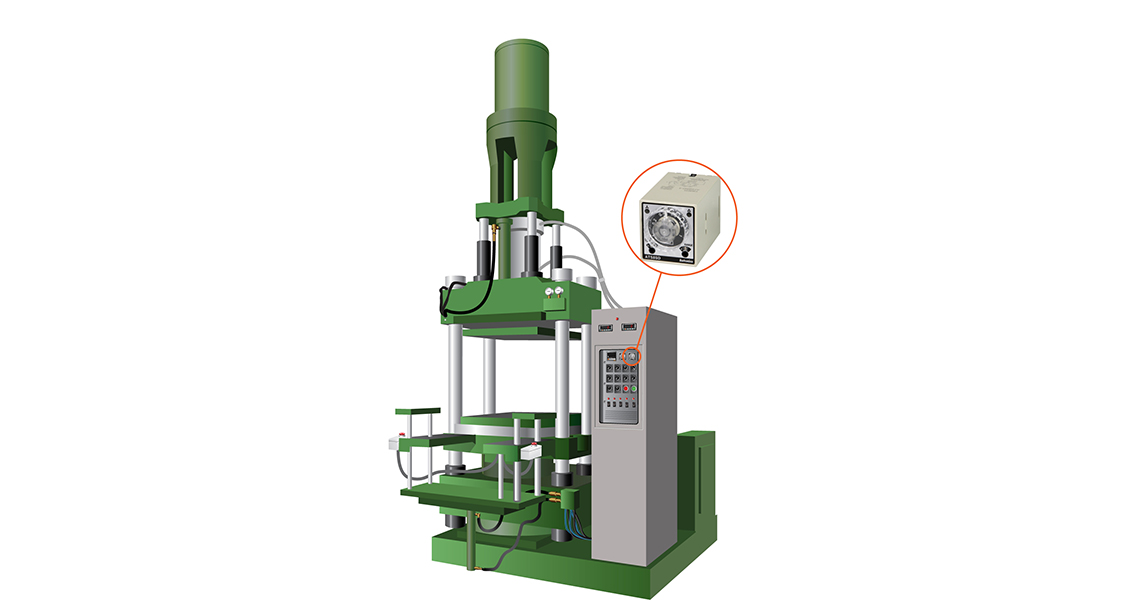

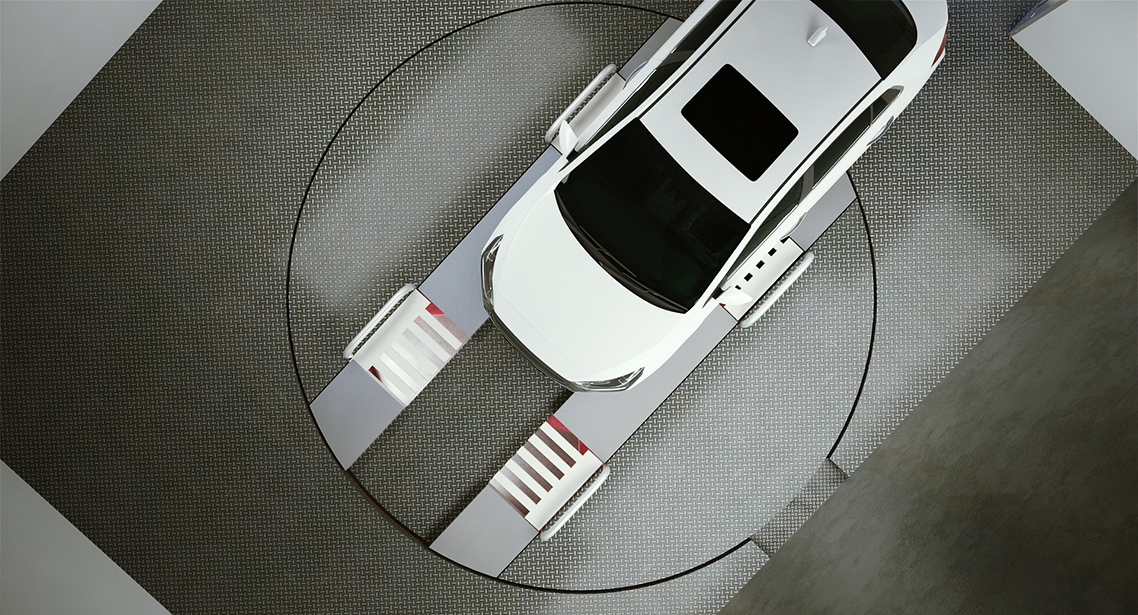

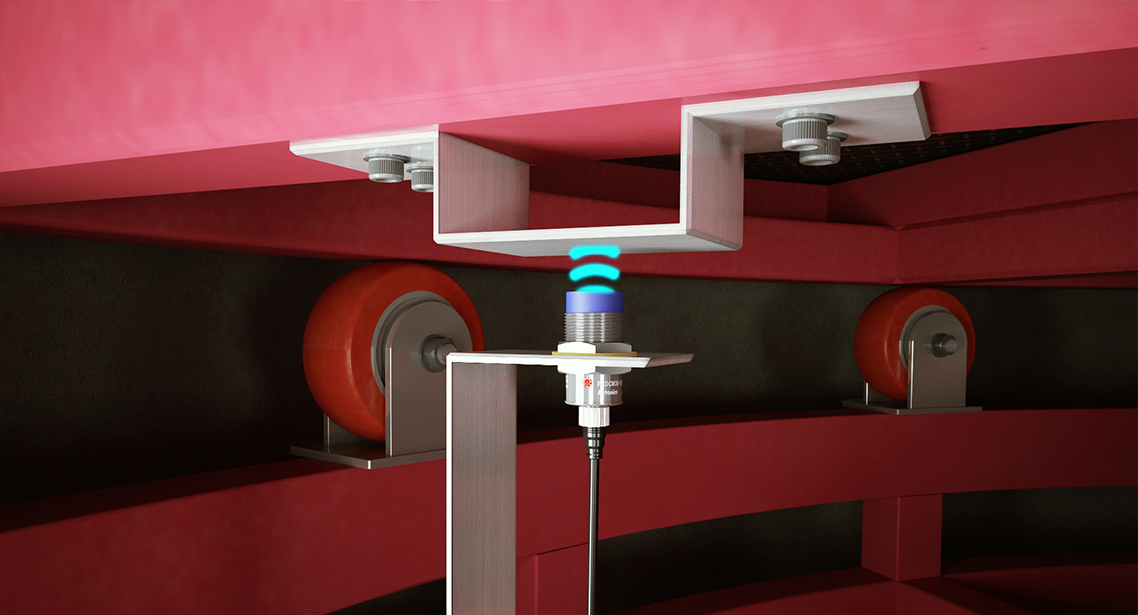

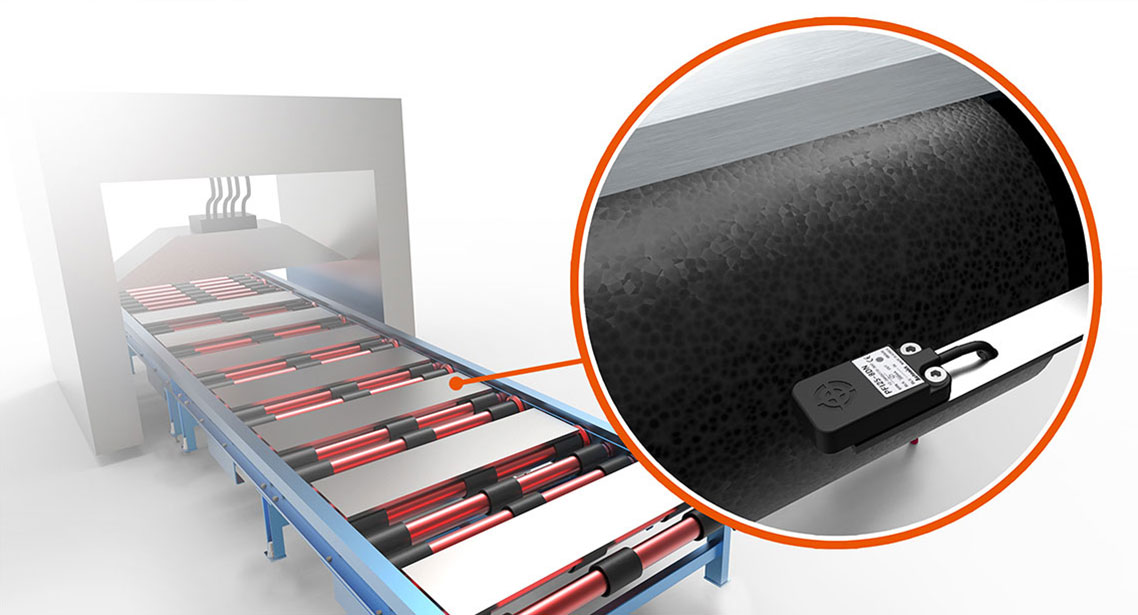

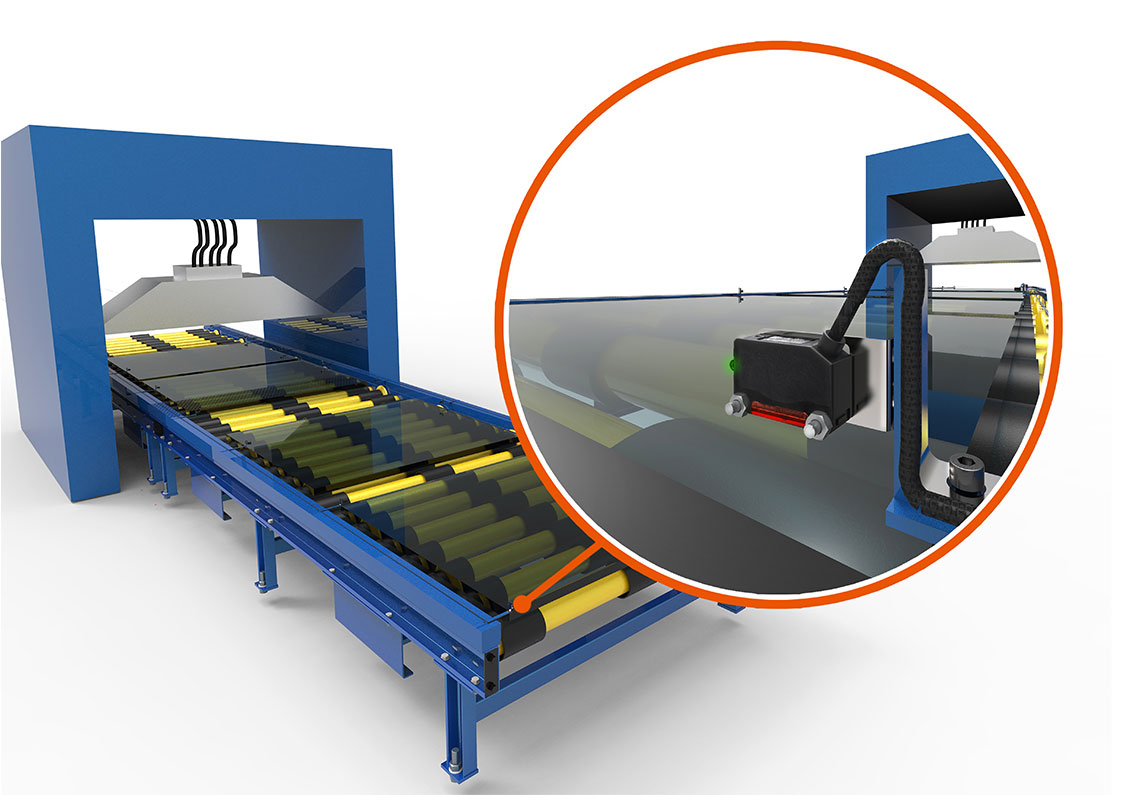

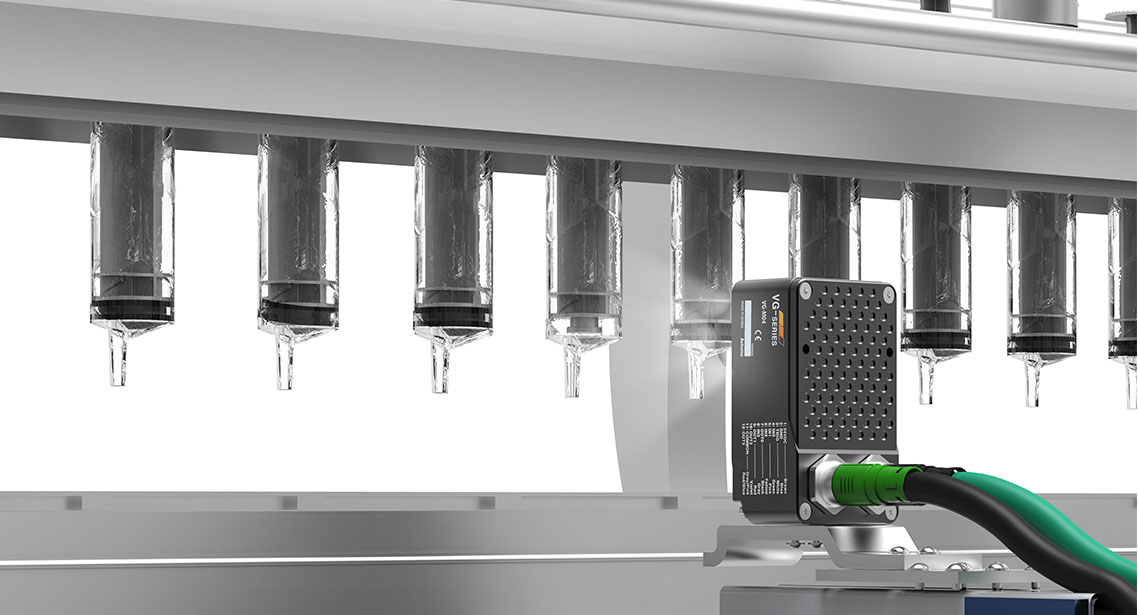

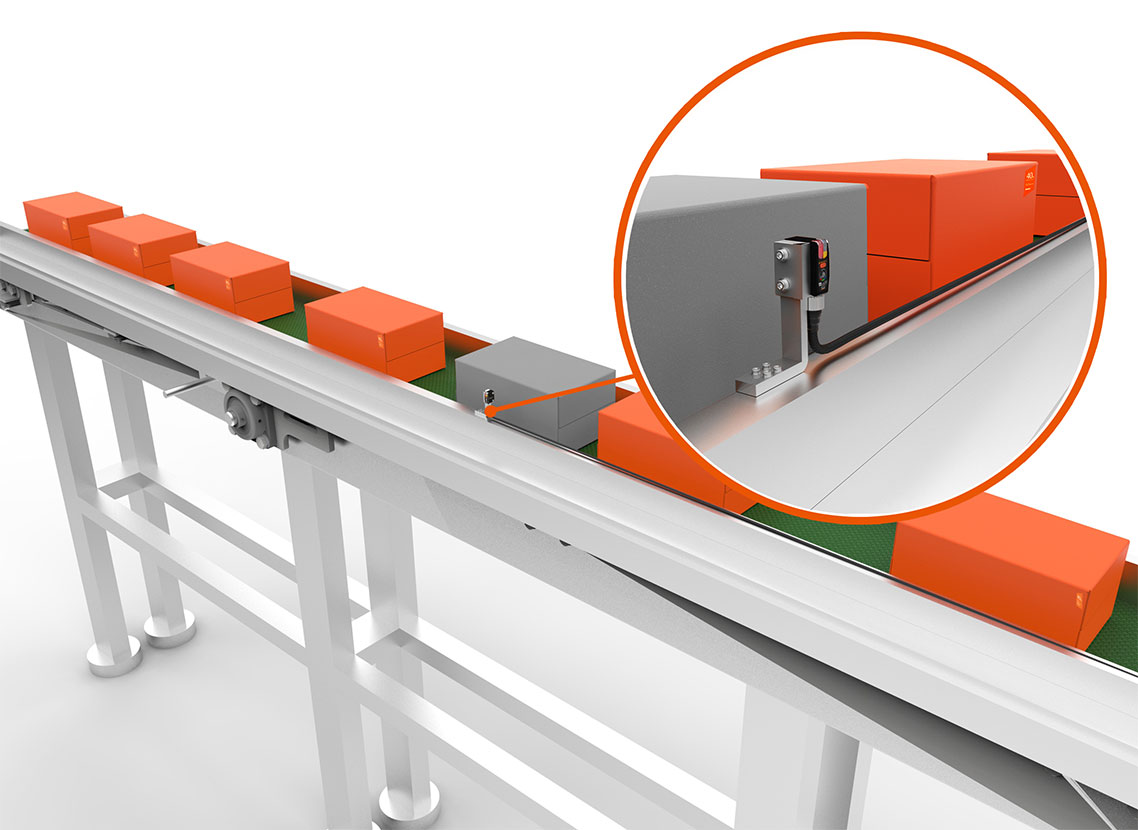

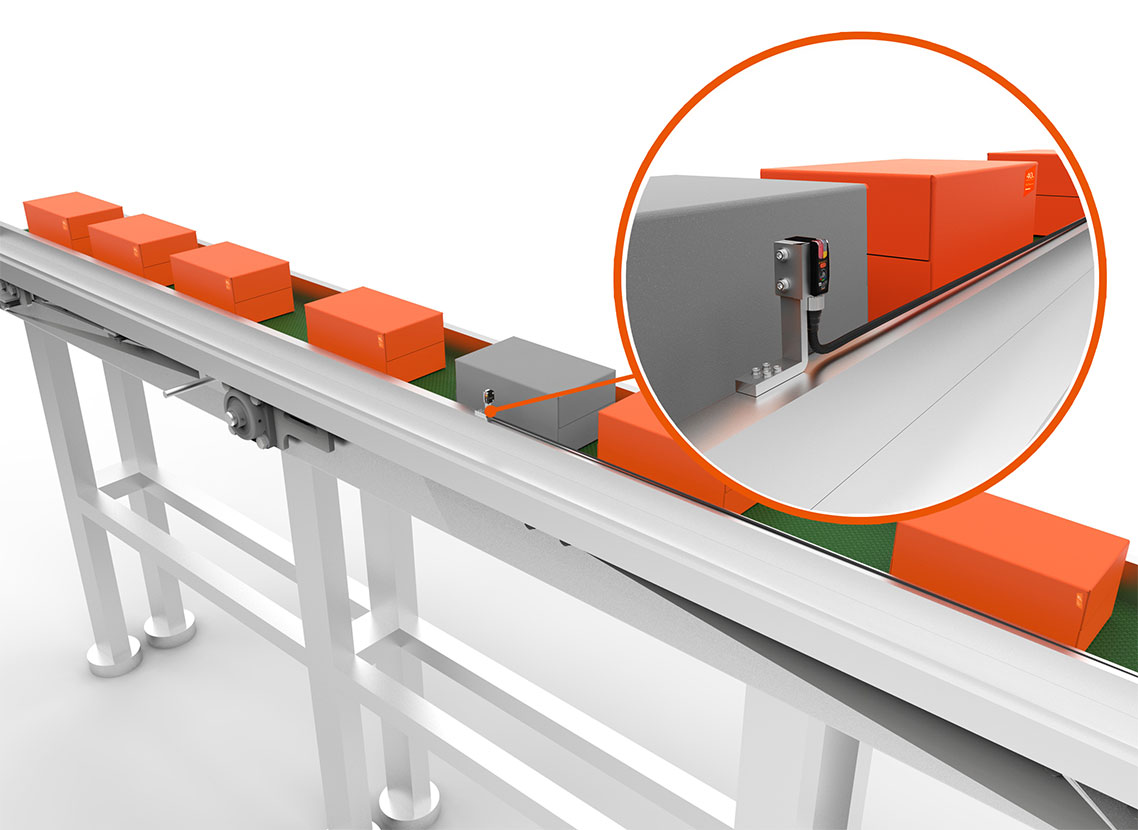

Problems: Beverage production lines where plastic containers, for example, are filled with liquid, have a short tact time and require a high degree of accuracy. The foodstuff industry is subject to particularly stringent levels of product control (e.g., HACCP). Generally speaking, filling control is performed by measuring the weight of the plastic container once in the empty state and then again after the filling has been completed. The difference is calculated to confirm that the weight agrees with the specified value. Data must be exchanged, however, with the host at each measurement, necessitating a complicated system configuration. If, as a result of the inspection, the filling weight is found to disagree with the specified value, correction is necessary. A way of performing the necessary sorting control quickly, simply, without sacrificing reliability is required. Mount ID Tags to the jigs holding the products. If round jigs are used, mount the ID Tags to the bottom of the jigs and install the Antenna underneath to ensure access even if the jigs turn around. Measure the weight of each container in the empty state and write the result to the ID Tag. Write the filling machine number to the ID Tag to distinguish it from machines at subsequent processes. Measure the weight of the container again after the filling is completed and write the total to the ID Tag. In the weight inspection process, read the empty-state weight and total weight from the ID Tag and check the difference at the host system. At this point, if the difference disagrees with the specified value, send the item to the correction process. At the sametime, read the filling machine number stored in the ID Tag.