The ER-X series offers an airless charge removal capability to eliminate the need for compressed air in addition to low pressure and high speed compressed air based modes. Furthermore, it supports dual-head configurations for expanded application coverage.

|

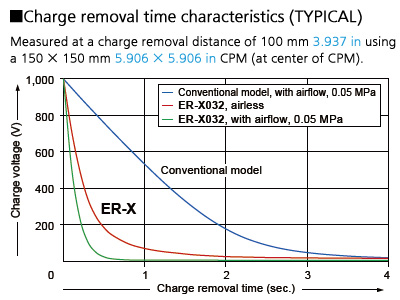

By applying a compressed air source, the ion volume increases providing an improved tact time for substrate ionization. This makes the ER-X suitable for applications such as electronic paper and thin film solar cells, where charge removal time is directly linked to productivity.

The ER-X series can effectively remove surface charges with an air pressure of less than 0.05 MPa. With the advantage of minimal dust dispersion, it is suitable for charge removal in semiconductor, FPD (mobile panel), and other applications that require high degree of cleanliness. The presence of air also helps prevent adhesion of dust to the discharge needles, requiring less cleaning than in the airless charge removal mode.

|

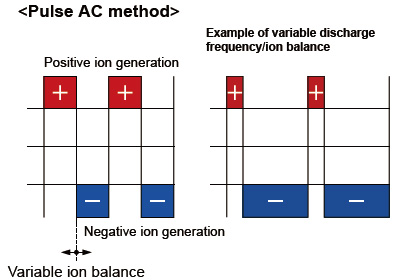

The ER-X series has adopted the pulse AC method that alternately applies positive and negative voltages to each discharge needle. This enables generation and discharge of a large amount of ions, resulting in faster charge removal. Select from eight pulse frequencies according to your application, from 100 Hz for charge removal on nearby or moving workpieces to 1 Hz for charge removal on far-away workpieces or in a threedimensional space. |

|

|

The ER-X series provides an automatic ion balance control mechanism that senses the amount of ions being generated (which changes according to environmental factors) and compensate for this deviation in the controller, thus maintaining a highly stable ion balance as an original operator setting. |

|

|

|

The pulse AC method enables the ER-X001 to generate

and discharge a large amount of ions, which makes charge removal faster. Furthermore, as a spot type ionizer, it achieves the fastest charge removal of 0.3 sec. |

|

ER-X001 high-voltage unit |

|

|

|

|

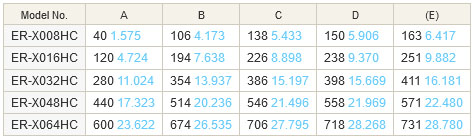

ER-X□HC |

|

|

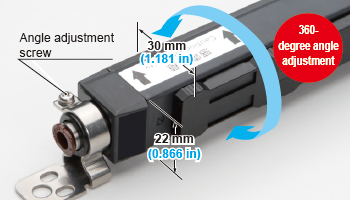

By thoroughly redesigning the discharge needle, we have created a super-compact slim head that combines high-speed charge removal*1 with a maintenance-saving design*2. The ER-X series can be embedded in, or retrofitted onto, equipment that did not provide enough space for antistatic measures in the past. |

|

|

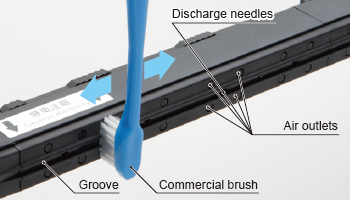

The ER-X series heads have a flat discharge face, allowing effortless cleaning of the discharge needles and air outlets by simply brushing along the groove provided. |

|

|

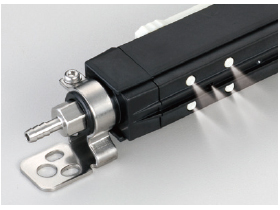

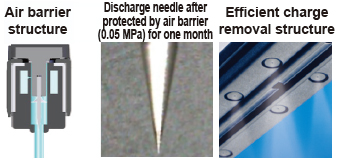

A barrier of clean air around the discharge needle keeps foreign matter from adhering to it, preventing degraded performance. |

|

In consideration of the manufacturing process (secondary cells etc.), the ER-X series heads neither use copper nor plate processing. This minimizes the risk of contamination with foreign substances.

|

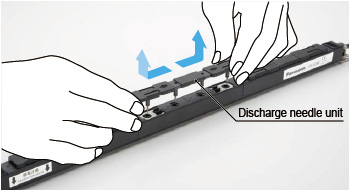

The removable discharge needle unit (including a set of four needles) substantially simplifies maintenance. To remove the unit, just slide it toward both ends as indicated by the arrows. |

|

|

|

The charging function is useful when charging paper or parts for static electricity adsorption transport.

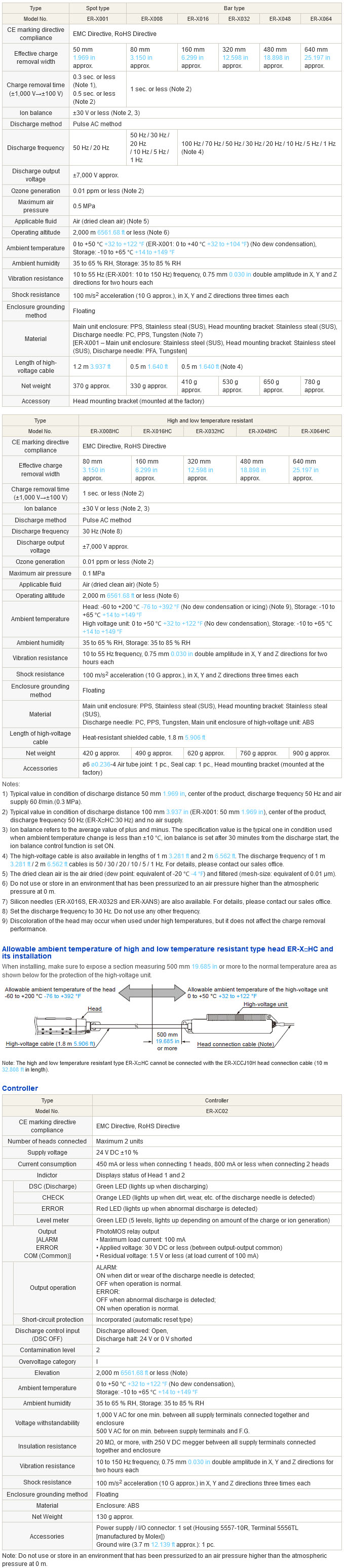

Notes:

1) Head 2 performs the ordinary charge neutralizing operation.

2) The ER-X001 cannot use the charging function.(Discharge operation stops.)

|

Head

|

|

Head

|

Head

|

Controller

|

Head connection cable

|

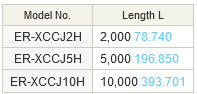

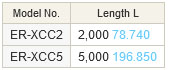

・Length L

Power cable (Optional)

|

・Length L

AC adapter (Optional)

|

|

| TITLE | DOCUMENT TYPE | SIZE |

| Pulse AC Method Area Ionizer ER-X | Catalog | 7752 KB |

|---|---|---|

| Static Control Devices Selection Guide | Catalog | 11813 KB |

| ER-X | Manual | 1366 KB |

| ER-XH | Manual | 346 KB |

| ER-XHC | Manual | 304 KB |

| ER-XACVR [Discharge Part Protective Cover] | Manual | 435 KB |

| ER-XAPS [AC Adapter] | Manual | 222 KB |