White PV display and new LCD with greatly improved visibility.*

* 100 times higher contrast ratio than the E5[]Z.

White PV display and new LCD with greatly improved visibility.*

* 100 times higher contrast ratio than the E5[]Z.

The white LCD display is easy to read in the subdued lighting conditions.

The display remains easy to read even from wide viewing angles.

The compact and space-saving design of the new E5CC/E5EC/E5AC controller generation requires less space behind the panel (60 mm), allowing quick snap-mounting and easy installation even under very cramped conditions.*

* Excluding E5CC-U and E5DC

The E5CC/E5CC-U/E5EC/E5AC/E5DC series is extremely easy to operate using the instrument’s five front keys.

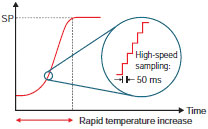

With key features like simplicity in operation, Omron’s patented PID control, and 50ms sampling period, the E5CC/E5CC-U/E5EC/E5AC/E5DC sets a new standard in fast and precise temperature regulation.

Sampling Rate Sufficient to Handle Rapid Increases in Temperature

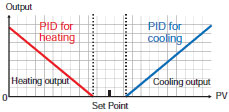

The heating and cooling PID can each be set individually. Also, autotuning (AT) will automatically set the PID constants.

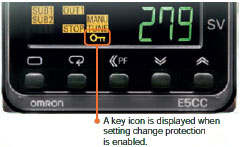

You can disable key operations to help prevent incorrect setting change.

| Power supply voltage |

A in model number: 100 to 240 VAC, 50/60 Hz D in model number: 24 VAC, 50/60 Hz; 24 VDC |

|

|---|---|---|

| Operating voltage range | 85% to 110% of rated supply voltage | |

| Power consumption | 7.0 VA max. at 100 to 240 VAC, and 4.2 VA max. at 24 VAC or 2.4 W max. at 24 VDC | |

| Sensor input |

Temperature input Thermocouple: K, J, T, E, L, U, N, R, S, B, C/W, or PL II Platinum resistance thermometer: Pt100 or JPt100 Infrared temperature sensor (ES1B): 10 to 70°C, 60 to 120°C, 115 to 165°C, or 140 to 260°C Analog input Current input: 4 to 20 mA or 0 to 20 mA Voltage input: 1 to 5 V, 0 to 5 V, or 0 to 10 V |

|

| Input impedance |

Current input: 150 Ω max., Voltage input: 1 MΩ min. (Use a 1:1 connection when connecting the ES2-HB/THB.) |

|

| Control method | ON/OFF control or 2-PID control (with auto-tuning) | |

|

Control output |

Relay output |

SPST-NO, 250 VAC, 5 A (resistive load), electrical life: 100,000 operations, minimum applicable load: 5 V, 10 mA |

|

Voltage output (for driving SSR) |

Output voltage: 12 VDC ± 20% (PNP), max. load current: 40 mA, with short-circuit protection circuit (The maximum load current is 21 mA for models with two control outputs.) |

|

|

Linear current output |

4 to 20 mA DC/0 to 20 mA DC, load: 500 Ω max., resolution: approx. 10,000 | |

|

Auxiliary output |

Number of outputs | 1, 2, or 3 (depends on model) |

|

Output specifications |

SPST-NO relay outputs, 250 VAC, Models with 2 outputs: 3 A (resistive load), Electrical life: 100,000 operations, Minimum applicable load: 10 mA at 5 V |

|

|

Event input |

Number of inputs | 2 or 4 (depends on model) |

|

External contact input specifications |

Contact input: ON: 1 kΩ max., OFF: 100 kΩ min. | |

| Non-contact input: ON: Residual voltage: 1.5 V max., OFF: Leakage current: 0.1 mA max. | ||

| Current flow: Approx. 7 mA per contact | ||

| Potentiometer input | 100 Ω to 10 kΩ | |

| Setting method | Digital setting using front panel keys | |

| Indication method |

11-segment digital display and individual indicators Character height: PV: 25.0 mm, SV: 15.0 mm |

|

| Multi SP |

Up to eight set points (SP0 to SP7) can be saved and selected using event inputs, key operations, or serial communications. |

|

| Bank switching | None | |

| Other functions |

Manual output, heating/cooling control, loop burnout alarm, SP ramp, other alarm functions, heater burnout (HB) alarm (including SSR failure (HS) alarm), 40% AT, 100% AT, MV limiter, input digital filter, self tuning, PV input shift, run/stop, protection functions, temperature status display, moving average of input value, FB moving average |

|

|

Ambient operating temperature |

-10 to 55°C (with no condensation or icing), for 3-year warranty: -10 to 50°C (with no condensation or icing) |

|

| Ambient operating humidity | 25% to 85% | |

| Storage temperature | -25 to 65°C (with no condensation or icing) | |

| Altitude | 2,000 m max. | |

| Recommended fuse | T2A, 250 VAC, time lag, low shut-off capacity | |

| Installation environment | Installation Category II, Pollution Class 2 (IEC 61010-1 compliant) | |

| Input type | Current | Voltage | |||

|---|---|---|---|---|---|

| Input specification | 4 to 20 mA | 0 to 20 mA | 1 to 5 V | 0 to 5 V | 0 to 10 V |

| Setting range |

Usable in the following ranges by scaling: -1999 to 9999, -199.9 to 999.9, -19.99 to 99.99 or -1.999 to 9.999 |

||||

| Set value | 25 | 26 | 27 | 28 | 29 |

Each alarm can be independently set to one of the following 19 alarm types. The default is 2: Upper limit. (see note.)

Auxiliary outputs are allocated for alarms. ON delays and OFF delays (0 to 999 s) can also be specified.

|

Set value |

Alarm type | Alarm output operation | Description of function | |

|---|---|---|---|---|

|

When alarm value X is positive |

When alarm value X is negative |

|||

| 0 |

Alarm function OFF |

Output OFF | No alarm | |

| 1 |

Upper- and lower-limit *1 |

|

*2 |

Set the upward deviation in the set point for the alarm upper limit (H) and the lower deviation in the set point for the alarm lower limit (L). The alarm is ON when the PV is outside this deviation range. |

|

2 (default) |

Upper-limit |

|

|

Set the upward deviation in the set point by setting the alarm value (X). The alarm is ON when the PV is higher than the SP by the deviation or more. |

| 3 | Lower-limit |

|

|

Set the downward deviation in the set point by setting the alarm value (X). The alarm is ON when the PV is lower than the SP by the deviation or more. |

| 4 |

Upper- and lower-limit range *1 |

|

*3 |

Set the upward deviation in the set point for the alarm upper limit (H) and the lower deviation in the set point for the alarm lower limit (L). The alarm is ON when the PV is inside this deviation range. |

| 5 |

Upper- and lower-limit with standby sequence *1 |

|

*4 |

A standby sequence is added to the upper- and lower-limit alarm (1). *6 |

| 6 |

Upper-limit with standby sequence |

|

|

A standby sequence is added to the upper-limit alarm (2). *6 |

| 7 |

Lower-limit with tandby sequence |

|

|

A standby sequence is added to the lower-limit alarm (3). *6 |

| 8 |

Absolute-value upper-limit |

|

|

The alarm will turn ON if the process value is larger than the alarm value (X) regardless of the set point. |

| 9 |

Absolute-value lower-limit |

|

|

The alarm will turn ON if the process value is smaller than the alarm value (X) regardless of the set point. |

| 10 |

Absolute-value upper-limit with standby sequence |

|

|

A standby sequence is added to the absolute-value upper-limit alarm (8). *6 |

| 11 |

Absolute-value lower-limit with standby sequence |

|

|

A standby sequence is added to the absolute-value lower-limit alarm (9). *6 |

| 12 |

LBA (alarm 1 type only) |

- | *7 | |

| 13 |

PV change rate alarm |

- | *8 | |

| 14 |

SP absolute value upper limit alarm |

|

|

This alarm type turns ON the alarm when the set point (SP) is higher than the alarm value (X). |

| 15 |

SP absolute value lower limit alarm |

|

|

This alarm type turns ON the alarm when the set point (SP) is lower than the alarm value (X). |

| 16 |

MV absolute value upper limit alarm *9 |

Standard Control

|

Standard Control

|

This alarm type turns ON the alarm when the manipulated variable (MV) is higher than the alarm value (X). |

|

Heating/Cooling Control (Heating MV)

|

Heating/Cooling Control (Heating MV) Always ON |

|||

| 17 |

MV absolute value lower limit alarm *9 |

Standard Control

|

Standard Control

|

This alarm type turns ON the alarm when the manipulated variable (MV) is lower than the alarm value (X). |

|

Heating/Cooling Control (Cooling MV)

|

Heating/Cooling Control (Cooling MV) Always ON |

|||

|

Indication accuracy (at the ambient temperature of 23°C) |

Thermocouple: (±0.3% of PV or ±1°C, whichever is greater) ±1 digit max. *1 Platinum resistance thermometer: (±0.2% of PV or ±0.8°C, whichever is greater) ±1 digit Analog input: ±0.2% FS ±1 digit max. CT input: ±5% FS ±1 digit max. Potentiometer input: ±5% FS ±1 digit max. |

|

|---|---|---|

|

Influence of temperature *2 |

Thermocouple input (R, S, B, C/W, PL II): (±1% of PV or ±10°C, whichever is greater) ±1 digit max. Other thermocouple input: (±1% of PV or ±4°C, whichever is greater) ±1 digit max. *3 Platinum resistance thermometer: (±1% of PV or ±2°C, whichever is greater) ±1 digit max. Analog input: ±1%FS ±1 digit max. CT input: ±5% FS ±1 digit max. |

|

| Influence of voltage *2 | ||

|

Influence of EMS. (at EN 61326-1) |

||

| Input sampling period | 50ms | |

| Hysteresis |

Temperature input: 0.1 to 999.9°C or °F (in units of 0.1°C or °F) Analog input: 0.01% to 99.99% FS (in units of 0.01% FS) |

|

| Proportional band (P) |

Temperature input: 0.1 to 999.9°C or °F (in units of 0.1°C or °F) Analog input: 0.1 to 999.9% FS (in units of 0.1% FS) |

|

| Integral time (I) |

Standard, heating/cooling, or Position-proportional (Close) 0 to 9999 s (in units of 1 s), 0.0 to 999.9 s (in units of 0.1 s) Position-proportional (Floating) 1 to 9999 s (in units of 1 s), 0.1 to 999.9 s (in units of 0.1 s) |

|

| Derivative time (D) | 0 to 9999 s (in units of 1 s), 0.0 to 999.9 s (in units of 0.1 s) *4 | |

|

Proportional band (P) for cooling |

Temperature input: 0.1 to 999.9°C or °F (in units of 0.1°C or °F) Analog input: 0.1 to 999.9% FS (in units of 0.1% FS) |

|

|

Integral time (I) for cooling |

0 to 9999 s (in units of 1 s), 0.0 to 999.9 s (in units of 0.1 s) *4 | |

|

Derivative time (D) for cooling |

0 to 9999 s (in units of 1 s), 0.0 to 999.9 s (in units of 0.1 s) *4 | |

| Control period | 0.1, 0.2, 0.5, 1 to 99 s (in units of 1 s) | |

| Manual reset value | 0.0 to 100.0% (in units of 0.1%) | |

| Alarm setting range | -1999 to 9999 (decimal point position depends on input type) | |

|

Affect of signal source resistance |

Thermocouple: 0.1°C/Ω max. (100 Ω max.) Platinum resistance thermometer: 0.1°C/Ω max. (10 Ω max.) |

|

| Insulation resistance | 20 MΩ min. (at 500 VDC) | |

| Dielectric strength | 2,300 VAC, 50/60 Hz for 1 min between terminals of different charge | |

| Vibration | Malfunction | 10 to 55 Hz, 20 m/s2 for 10 min each in X, Y, and Z directions |

| Resistance | 10 to 55 Hz, 20 m/s2 for 2 hrs each in X, Y, and Z directions | |

| Shock | Malfunction | 100 m/s2, 3 times each in X, Y, and Z directions |

| Resistance | 300 m/s2, 3 times each in X, Y, and Z directions | |

| Weight | Controller: Approx. 250 g, Mounting Brackets: Approx. 4 g × 2 | |

| Degree of protection | Front panel: IP66, Rear case: IP20, Terminals: IP00 | |

| Memory protection | Non-volatile memory (number of writes: 1,000,000 times) | |

| Standards |

Approved standards |

UL 61010-1, Korean Radio Waves Act (Act 10564) |

|

Conformed standards |

EN 61010-1 (IEC 61010-1): Pollution level 2, overcurrent category II, Lloyd's standards *5 | |

| EMC |

EMI EN 61326-1 *6 Radiated Interference Electromagnetic Field Strength: EN 55011 Group 1, class A Noise Terminal Voltage: EN 55011 Group 1, class A EMS: EN 61326-1 *6 ESD Immunity: EN 61000-4-2 Electromagnetic Field Immunity: EN 61000-4-3 Burst Noise Immunity: EN 61000-4-4 Conducted Disturbance Immunity: EN 61000-4-6 Surge Immunity: EN 61000-4-5 Voltage Dip/Interrupting Immunity: EN 61000-4-11 |

|

*1. The indication accuracy of K thermocouples in the -200 to 1300°C range, T and N thermocouples at a temperature of

-100°C max., and U and L thermocouples at any temperatures is ±2°C ±1 digit max. The indication accuracy of the

B thermocouple at a temperature of 400°C max. is not specified. The indication accuracy of B thermocouples at a

temperature of 400 to 800°C is ±3°C max. The indication accuracy of the R and S thermocouples at a temperature

of 200°C max. is ±3°C ±1 digit max. The indication accuracy of C/W thermocouples is (±0.3 of PV or ±3°C, whichever

is greater) ±1 digit max. The indication accuracy of PL II thermocouples is (±0.3% of PV or ±2°C, whichever is

greater) ±1 digit max.

*2. Ambient temperature: -10°C to 23°C to 55°C, Voltage range: -15% to 10% of rated voltage

*3. K thermocouple at -100°C max.: ±10°C max.

*4. The unit is determined by the setting of the Integral/Derivative Time Unit parameter.

*5. Refer to information on maritime standards in Shipping Standards on Catalog for compliance with Lloyd's Standards.

*6. Industrial electromagnetic environment (EN/IEC 61326-1 Table 2)

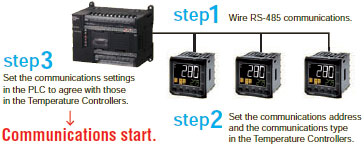

| Transmission line connection method | RS-485: Multidrop |

|---|---|

| Communications | RS-485 (two-wire, half duplex) |

| Synchronization method | Start-stop synchronization |

| Protocol | CompoWay/F, or Modbus |

| Baud rate | 9600, 19200, 38400, or 57600 bps |

| Transmission code | ASCII |

| Data bit length* | 7 or 8 bits |

| Stop bit length* | 1 or 2 bits |

| Error detection |

Vertical parity (none, even, odd) Block check character (BCC) with CompoWay/F or CRC-16 Modbus |

| Flow control | None |

| Interface | RS-485 |

| Retry function | None |

| Communications buffer | 217 bytes |

| Communications response wait time |

0 to 99 ms Default: 20 ms |

|

Programless communications *1 |

You can use the memory in the PLC to read and write E5[]C parameters, start and stop operation, etc. The E5[]C automatically performs communications with PLCs. No communications programming is required. Number of connected Temperature Controllers: 32 max. (Up to 16 for the FX Series) Applicable PLCs OMRON PLCs CS Series, CJ Series, CP Series, NJ Series, or NX1P Mitsubishi Electric PLCs MELSEC Q Series, L Series, FX3 Series, or iQ-R Series KEYENCE PLCs KEYENCE KV Series |

|---|---|

|

Component Communications *1 |

When Digital Temperature Controllers are connected, set points and RUN/STOP commands can be sent from the Digital Temperature Controller that is set as the master to the Digital Temperature Controllers that are set as slaves. Slope and offsets can be set for the set point. Number of connected Digital Temperature Controllers: 32 max. (including master) |

| Copying *2 |

When Digital Temperature Controllers are connected, the parameters can be copied from the Digital Temperature Controller that is set as the master to the Digital Temperature Controllers that are set as slaves. |

|

E54-CT1 E54-CT3 |

E54-CT1L E54-CT3L |

|

|---|---|---|

| Dielectric strength | 1,000 VAC for 1 min | 1,500 VAC for 1 min |

| Vibration resistance | 50 Hz, 98 m/s2 | |

| Weight |

E54-CT1: Approx. 11.5 g, E54-CT3: Approx. 50 g |

E54-CT1: Approx. 14 g, E54-CT3: Approx. 57 g |

| Accessories |

E54-CT3 Only Armatures (2) Plugs (2) |

None |

| CT input (for heater current detection) |

Models with detection for single-phase heaters: One input Models with detection for single-phase or three-phase heaters: Two inputs |

|---|---|

| Maximum heater current | 50 A AC |

| Input current indication accuracy | ± 5% FS ± 1 digit max. |

| Heater burnout alarm setting range *1 |

0.1 to 49.9 A (in units of 0.1 A) Minimum detection ON time: 100 ms *3 |

| SSR failure alarm setting range *2 |

0.1 to 49.9 A (in units of 0.1 A) Minimum detection OFF time: 100 ms *4 |

(Unit: mm)

The Waterproof Packing is provided with the Temperature Controller.

The degree of protection when the Waterproof Packing is used is IP66.

Also, keep the Port Cover of the E5EC/E5AC-800 securely closed.

To maintain an IP66 degree of protection, the Waterproof Packing and the Port Cover must be periodically replaced because they may deteriorate, shrink, or harden depending on the operating environment.

The replacement period will vary with the operating environment.

Check the required period in the actual application.

Use 3 years or sooner as a guideline.

If a waterproof structure is not required, then the Waterproof Packing does not need to be installed.

One pair is provided with the Controller.

Order this Adapter separately if it becomes lost or damaged.

Maximum continuous heater current: 50 A (50/60 Hz)

Number of windings: 400±2

Winding resistance: 18±2 Ω

Maximum continuous heater current: 120 A (50/60 Hz)

(Maximum continuous heater current for an OMRON Digital Temperature Controller is 50 A.)

Number of windings: 400±2

Winding resistance: 8±0.8 Ω

| TITLE | DOCUMENT TYPE | SIZE |

| E5[]C-800 | Catalog | 19100 KB |

|---|---|---|

| E5[]C (Simple Type) | Catalog | 2941 KB |