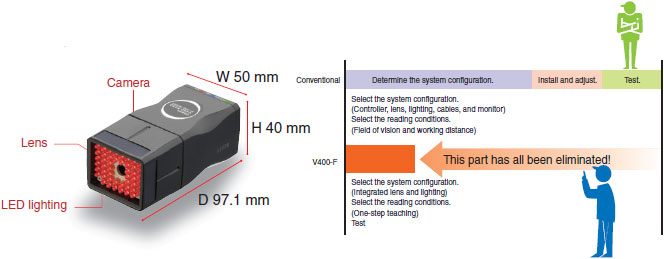

The selection process is greatly simplified by the integrated lens and lighting design.

No more worrying about having to match each workpiece to a vast number of lens and lighting combinations.

The selection process is greatly simplified by the integrated lens and lighting design.

No more worrying about having to match each workpiece to a vast number of lens and lighting combinations.

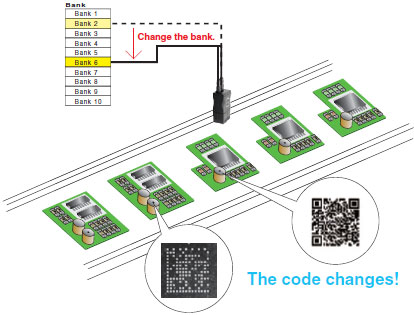

The Auto Bank Change function lets the operator automatically change preset reading conditions recorded in banks. Up to five banks can be set in advance to greatly reduce bothersome steps when changing the line process.

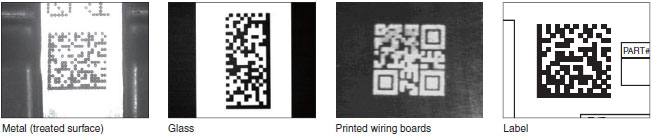

We have achieved high accuracy for directly marked codes by combining the industry's most advanced reading algorithm with lighting control that is optimized for data reading. Even directly marked 2D codes printed onto materials with varying reflectivity, such as metals, printed wiring boards, and glass, can be read with excellent accuracy.

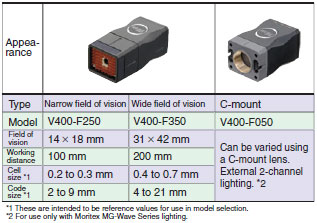

There are three 2D Code Readers to choose from to match your application. This enables flexible response to different workpieces and production site conditions. Use the C-mount model when specific settings are necessary for the lighting or lens.

The Retry and Preprocess Filtering functions allow stable reading even under harsh conditions. They eliminate the effects of printing conditions and workpiece changes, such as oil, ambient light, and varying substrate types.

Multiple readings can be taken while changing the exposure time and adjusting the brightness of the light.

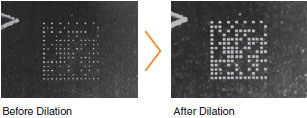

Three of the following four types of filtering can be used for images that have been taken: Smoothing, Dilation, Erosion, and Median.

last update: March 01, 2016

| Model | V400-F050 | V400-F250 | V400-F350 |

|---|---|---|---|

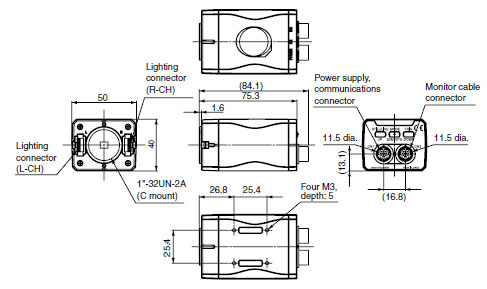

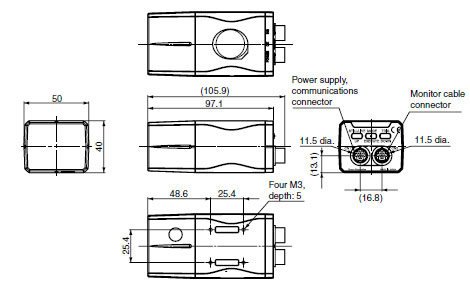

| Dimensions | 40 ´ 50 ´ 75.3 mm | 40 ´ 50 ´ 97.1 mm | |

| Working distance (WD) | Depends on the lens. | Approx. 100 mm | Approx. 200 mm |

| Field of vision | Depends on the lens. | Approx. 14 ´ 18 mm | Approx. 31 ´ 42 mm |

| Lighting | Up to two can be

directly powered |

Red LED | |

| Applicable codes | Data Matrix, ECC200, 10 ´ 10 to 64 ´ 64, 8 ´ 18 to 16 ´ 48,

QR Code (Models 1, 2), 21 ´ 21 to 57 ´ 57 (Versions 1 to 10) |

||

| Image sensor | 1/3" CCD | ||

| Effective pixels | 640 ´ 480 pixels | ||

| Power supply voltage | 24 VDC ±10% | ||

| Power consumption | 0.5 A max. (power consumption for monitor, not included) | ||

| Insulation resistance | 20 MΩ min. | ||

| Withstand voltage | 1,000 VAC for 1 min | ||

| Leakage current | 0.25 mA max. | ||

| Noise resistance | Power line: 2 kVp-p, Pulse width: 50 ns, Rise time: 5 ns,

Consecutive burst time: 15 ms, Cycle: 300 ms |

||

| Applicable standards | CE: EN 61326:1997, +A1:1998, +A2:2001 (EMI: Class A) | ||

| Vibration resistance | 10 to 150 Hz, 0.35-mm half-amplitude (maximum acceleration: 50 m/s2)

10 times for 8 minutes each in 3 directions |

||

| Shock resistance | 150 m/s2 3 times each in 6 directions | ||

| Ambient humidity | Operating: 0 to 45°C, Storage: -25 to 65°C | ||

| Ambient temperature | Operating/storage: 25% to 85% (with no icing or condensation) | ||

| Ambient environment | No corrosive gasses | ||

| Degree of protection | None | IEC 60529 IP67 | |

| Weight | Approx. 130 g | Approx. 150 g | |

last update: March 01, 2016

last update: March 01, 2016

| TITLE | DOCUMENT TYPE | SIZE |

| V400-F | Catalog | 1597 KB |

|---|---|---|

|

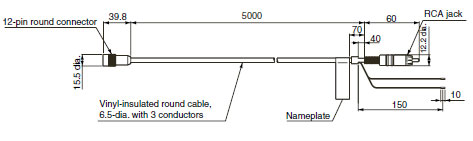

V400-F050/F250/F350

2D code reader |

Manual | 3133 KB |

|

V400-F050/F250/F350

2D code reader instruction sheet |

Manual | 668 KB |